|

Purpose of the

R-725 Modifications - For Adcock Direction Finders - or - Was that just

a Cover Story? - The usual purpose that is given for the

R-725 mods was for compatibility with military portable direction

finders that used four vertical antennae per installation along with

three receivers. The DF system used went back to the Bellini-Tosi type

of DF set-up that used two crossed loop antennae with a rotating loop

inside to create a radio-goniometer. Bellini and Tosi had discovered

that crossed loop antennae would "re-radiate" the signal they were

receiving within the small field inside the antenna's space. The

"re-radiated" signal retained all of the directional properties of the

original signal and could be measured for varying signal intensity

dependent on direction. The crossed loop antenna size didn't affect it

frequency of operation allowing for reduction in the size of DF loops on

LW. Of course, the original Bellini-Tosi system dated from around 1900

and the system was sold to the Marconi Company around 1907. By the early

twenties, vacuum tube amplifiers were being added to increase

performance capabilities of the DF antennae systems. The most common B-T

DF systems used the crossed loops but some larger systems used the

four-square vertical antenna system and a rotational loop (the

goniometer) within the square. This system was developed by Adcock

during WWI and because the connections to and from the four square

verticals were underground it didn't respond to skywave propagation and

allowed ground wave DFing over long distances. The B-T DF and Adcock

systems continued to evolve and improve and the systems were used

throughout WWII. During WWII, oscilloscope displays began to be used for

direction indications. After WWII, larger DF systems continued to be

developed up to the mammoth "elephant cage" antennae ("Wullenweber" was

the actual name) that were over a thousand feet in diameter and

consisted of several "rings" of circular antennae all working to provide

accurate DFing over great distances and wide frequency spans. By the

1990s, most of these large arrays were becoming obsolete and nowadays

most have been dismantled.

The mechanical filters used in the R-390A resulted in

signal path phase shifts that caused errors to show up in the DFing

electronics. When used with the four square antennas, the low frequency

modulation added via the radio-goniometer interacted with the mechanical

filters creating the error. Early versions of this DF set-up had used

R-390 receivers and the radio-goniometer was located quite a distance

from the receivers to reduce any interference. In the 1960s, the USAF

wanted to reduce the size of the entire DF system so it could be towed

around on a trailered hut. This meant the radio-goniometer had to be in

the same room as the receivers. This was going to require some

protection to certain receiver circuits. The R-390 had been out of

production for several years, so the solution was to design the new

portable system to use modified R-390A receivers that could be easily

purchased. Arvin Industries was the main contractor with Servo also

doing some rework. The modified receivers would have the Series 500 IF

module, essentially a R-390 IF module that was slightly updated to not

require any rework to the R-390A receiver it was installed into. That

eliminated the mechanical filter phase shift problem. Additionally, with

the close proximity to the radio-goniometer, a 60hz hum appeared on the

PTO tube filament and that also interfered with the LF modulation of

the DF system. A special "hum bucker" chassis was added to the receiver

that essentially operated the VFO tube, the BFO tube and the 3TF7

Ballast tube on +25vdc. Also, a grounded ferrous metal shield was added

to the PTO housing to prevent hum "pick up." Arvin bought new R-390A

receivers in 1967 from Electronic Assistance Corporation and the

modifications were installed and, when complete, the receiver was tagged

as "R-725/URR." The tags will generally show Arvin Industries as the

contractor but sometimes Servo will be encountered. The quantity of

R-725/URR receivers needed by the USAF was fairly small (less than 300,

according to Moe) and thus today the R-725 is seldom encountered.

Contact number on the R-725/URR was DAAB05-67-C-2338.

However, was there another purpose that was the "real"

reason that the R-725 was created? According to an article that appeared

in Electric Radio in January 2006 by Chuck Teeters, there was a "top

secret" purpose for the R-725 and the receiver "mods" were initially

created for that "secret" project. The R-725 was a product resulting

from the Cold War jamming that was common between the USA and the USSR.

In the mid-to-late 1960s, there was a new system that was being

developed called "Tropicom" that was an upgrade to the antennas and

transmitters to improve HF communications for the military. The upgrades

also included the incorporation of the "F9c" anti-jamming/crypto system.

The F9c system used a spread spectrum transmission of digital noise and

signal that ran through a digital encrypo-key generator that had 144

stages of looped-feedback that also fed through phase modulators to

maintain proper phase relationships of the signal and noise. When used

with a R-390A on the receive end, the phase changes in the mechanical

filters interfered with the recombination process and the system didn't

work. When used with R-390s with a standard IF amplifier circuit, the

F9c system worked fine. Since the R-390 dated from the early-1950s,

there was only a limited supply of those receivers still available and

those that were available needed constant maintenance. The ultimate

solution was to have new R-390A receivers built with new-build R-390 IF

modules installed.

In order to keep the F9c project "secret," the actual

use of the R-725 couldn't be known to those outside the project. Since

there really was the Adcock DF system upgrades that really did need a

non-mechanical filter type R-390A, the R-725 was directed to be built

for the DF purpose only. However, those running the F9c project had the

R-725 order quantity doubled and half of the R-725 receivers were

procured for F9c use while the other half went to the DF systems. The

secret classification stayed on with the F9c system and it was used for

quite a long period with many upgrades over the years. So, even though

half of the R-725 receivers were used in direct finders, the other half

had a "secret life" used in the anti-jamming/crypto communications world

of the NSA, USAF and the Signal Corps.

Testing the

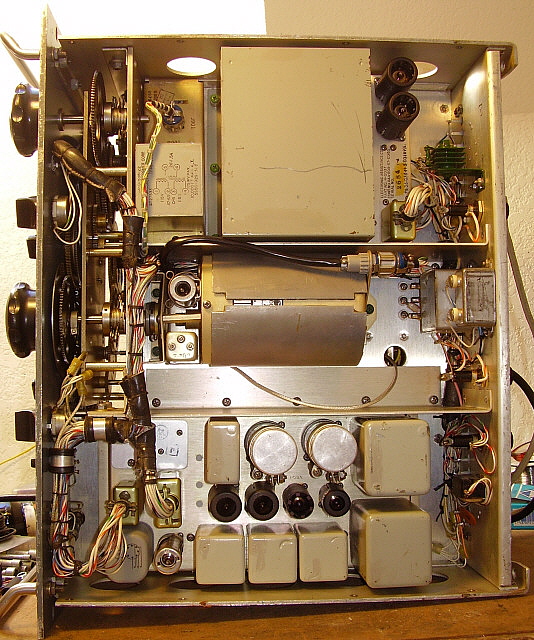

R-390A with a Series 500 IF Module - With the donation of

the Arvin R-725 data plate it looked like I had all of the parts to

build-up a R-725 if I could supply a complete 1967 EAC R-390A. According

to Moe, when Arvin built-up the R-725 receivers they purchased new '67

EAC R-390As direct from EAC to fulfill the contract, thus all Arvin

R-725s are converted '67 EAC R-390A receivers. I decided to use my '67

EAC SN: 974 R-390A because this receiver had recently been partially

"cannibalized" to complete another EAC R-390A. I needed to replace a

defective RF transformer on the 2-4mc antenna stage and do some minor

alignments. Luckily, the "junk" R-725 RF deck supplied a good RF

transformer. The first step was to check out and test the Series 500 IF

module. One of the IF transformer cans was severely dented and needed

"body work" to correct. All of the tubes were missing. I checked over

the underneath and all components appeared to be in good shape. I gave

the Band Width switch a DeOxit treatment. I needed tubes and tube

shields. I found all of the tubes in my tube storage. The shields were

"borrowed" from the EAC IF deck as was the 3TF7. The Series 500 is a

"tight fit" but it does fit (see above photo.) The chassis is somewhat

longer so the captive screws are located on the chassis rather than on

the flange. The Band Width and BFO shafts are shorter than on the

standard IF deck. The input and output coax connectors are in a

different location but the cables reach easily. There is no clearance

for the rear IF output cable as it is directly behind one of the 12AU7

tubes. The junk R-725 main frame even had the rear IF output connector

totally removed. A special connector is required for the IF output on

the R-725 conversion. The Amphenol connector has to be turned 90 degrees

but everything lines up and there is ample flexibility to allow for this

connection.

With power applied, everything came up as expected. The

first thing noticed was that the IF Gain must have been at "maximum" -

it was. After some testing and listening, I reduced the IF gain by about

50 percent. This provided ample IF gain and much lower noise levels.

Carrier Level was adjusted on 15mc to zero with the antenna

disconnected. BFO was zeroed. I didn't do a 455kc IF alignment since

this was just a "check out" but the IF deck already seemed to be

performing better than expected.

|

Installing the "Hum Bucker" - Thanks to Craig

W6DRZ, I had a C-D with data on all of the R-390A variants,

including the R-725. The R-725 manual had step-by-step

instructions for the installation of the "hum bucking" chassis

plus a schematic that showed what was accomplished after the

chassis was "wired" into the circuit. The "hum bucker" consists

of a small 25vac transformer, a resistor divider network that's

connected to B+, a connector and chassis. Essentially, the "hum

bucker" modification first isolates the filaments of the VFO

tube, the BFO tube and the 3TF7 ballast tube and connects these

components in series to the the 25vac winding of the small

transformer. This winding is NOT connected to chassis but is

"floating." The 25vac also has a resistor network that has a

220K resistor from B+ to one side of the 25vac winding and a 33K

resistor from that junction to chassis. This divider results in

about +25vdc "riding on" the "floating" 25vac tube filaments

which results in the DC "swamping" any 60hz hum on the VFO and

BFO tube filaments. If pin 3 of the VFO tube is measured

referenced to chassis it should be +25vdc.

To integrate the "hum bucker" into the circuit

requires wiring a harness of six wires from P-119 on the "hum

bucker" into various parts of the R-390A. Of these six wires,

two are routed to the Power Supply module connector (AC in,) one

is routed to the IF module connector (Hum Bucker Filament

voltage to VFO, BFO, 3TF7 with original R-390A wire

disconnected) one is routed to the AF module connector (B+,) one

is routed to the PTO connector (VFO tube filament series string

return) and one is connected to the main frame chassis. Luckily,

the actual R-725 junk main frame that I had still had the "hum

bucking" wiring intact although this six-wire cable was cut to

remove the "hum bucking" chassis in the past. Again, luckily, I

had the exact same "hum bucking" chassis, so I had the other end

of the wiring harness with the proper connector. The six wires

are laced and some wires are routed though plastic sleeving. I

wasn't able to find any stranded 20 gauge wire that was even

close to the original wire used so I decided to restore the

original harness. I removed the remaining side of the original

harness from the junk R-725 main frame. I made a drawing of how

the wire routing was originally done. Luckily, where the harness

was cut actually ends up down next to the PTO so the repair

isn't visible. By carefully splicing the six wires together the

overall length of the harness was only shortened by about a half

an inch. The finished repair was covered by black shrink tubing

to make the repair look authentic.

Each of the six wires were routed next to the

main front-to-rear harness next to the PTO. The six-wire harness

is tied to the main harness with waxed lacing string in six

places. Each wire has to be then routed to the specific module

connector to make the proper connections. The Amphenol

connectors have to have their covers pulled back to access the

connector pins. Most of the connections parallel the wires

already soldered. There is ample space to loop the new wire

connection thru the terminal and solder it. The original

sleeving is then returned over the terminal when the soldering

is complete on each connector. The Filament connection to the IF

module connector has to have the original wire disconnected and

then taped (or insulated.) Then the new wire from the "hum

bucker" is soldered in its place. The PTO connector has to be

accessed to add the filament connection to pin C to complete

filament routing. This completes the addition of the "hum

bucker" to the circuit. |

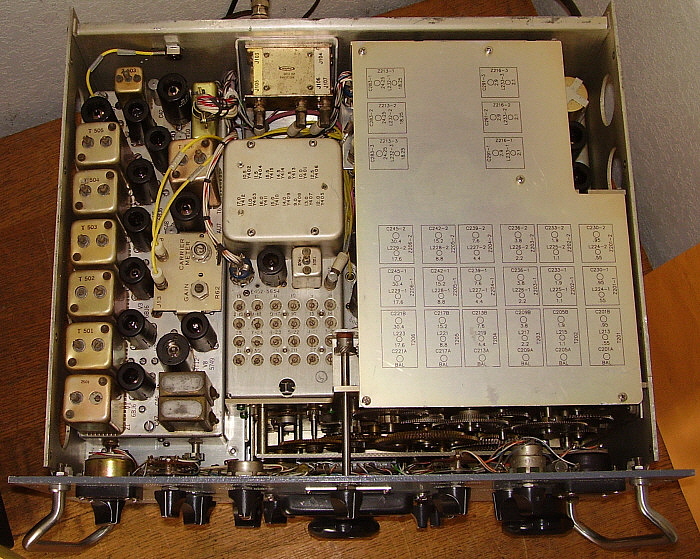

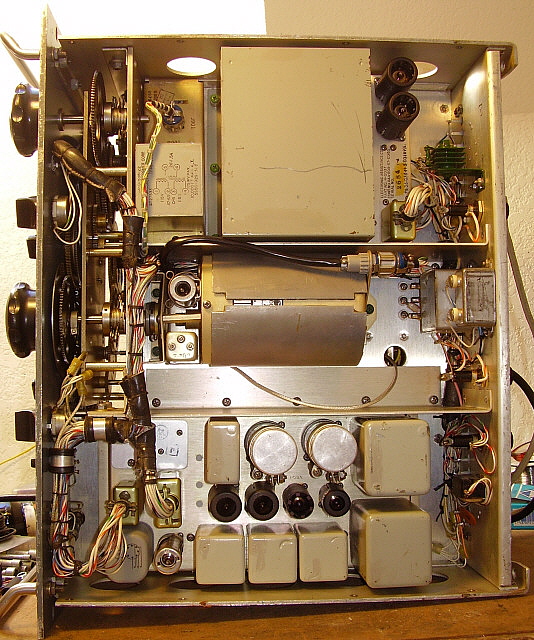

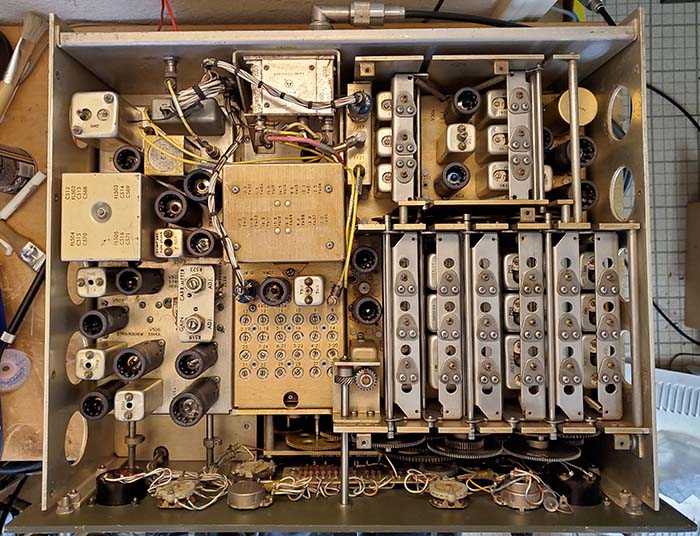

photo above: The

underside of the R-725 showing how the "hum bucker" chassis is

mounted in front of the power supply. The hum bucker harness is

routed thru the receiver harness to the various module power

plugs for connections. Also note the ferrous metal shield over

the PTO. |

Mounting the

Hum Bucker Chassis - Mechanically, the "hum bucker" is

mounted in front of the R-390A power supply. This requires a bracket

with pem-nut on the PTO side plate and two holes on the outer side panel

to mount the "hum bucker" chassis. I removed the PTO side plate from the

"junker" R-725 main frame because it had the original bracket already

mounted. I removed the original PTO side plate from the R-390A and

installed the R-725 side plate in its place. I carefully measured the

original "junker" R-725 main frame side panel for the correct location

of the two mounting holes. I then marked and drilled the R-390A side

panel in the original manner. These modifications allowed the "hum

bucker" chassis to mount exactly as it did in the original R-725. Now

the "hum bucker" installation was electronically and mechanically

complete. On to the PTO next.

Testing and

Calibration the PTO - I'm using the original Cosmos PTO

from the junk R-725 main frame. This PTO already had the mod installed

that lifted pin 3 of the VFO tube from chassis. Then a wire was

connected to pin 3 and it was routed back to the PTO connector where it

is connected to the unused pin C. Also, a .01uf ceramic disk was

installed from tube socket pin 3 to chassis. The PTOs that were used in

the R-725 had a ferrous metal shield installed over the can of the PTO

and this PTO did have that shield installed (eliminates any radiated hum

if the 24vac PTO heater is operated. Since it's 60~ AC, the shield has

to be ferrous metal.) I have a R-390 PTO test

fixture that was given to me by W6MIT. The test fixture allows powering

the PTO and employs a digital turns-counting dial to accurately set the

end-point error to <0.5kc. I had to supply +195vdc B+, Regulated

+150vdc, 6.3vac and chassis ground. Output was measured from the coaxial

cable of the PTO using a digital frequency counter. I used a Lambda 25

for the B+ and 6.3vac and a regulated +150vdc supply. With the PTO on

the fixture and powered up, the first step was to adjust the PTO output

to 2455kc, then set the counter to 00.0 and tighten the coupler. The

fixture counter works the opposite to how the PTO functions in the

receiver. Since it's a mechanical readout on the drive rotation it

doesn't really matter and our actual check was to verify that the PTO

output changes from 2455kc to 3455kc in exactly ten turns. A quick check

revealed that the end-point error was close to 1.0kc. I ran thru each

turn to check linearity and this PTO was "right on." If it had been

necessary to adjust the PTO end-point I would have followed the

procedure as detailed in the PTO section further up this web page. To

install the PTO only requires that it be set to 3455kc output with the

R-390A having xx.000 on Veeder-Root counter. When the R-390A Veeder-Root

counter is set to xx.000 then the Oldham coupler aligns correctly. The

power connector is installed and the output coax connected to the RF

module. This completed the PTO modifications and, in fact, completed all

of the R-725 mods necessary.

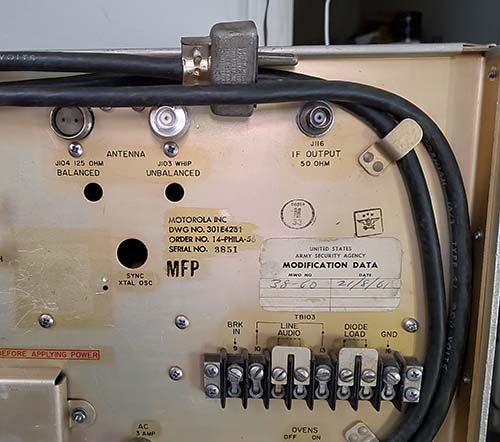

Installing the

Special Right-angle Coax to BNC fitting for IF Output -

If it's attempted to fit the original IF output coax cable onto the

original coax box BNC Jr to BNC output fitting, it will become obvious

that there isn't enough clearance due to the 12AU7 tube directly in

front of the connector. For the R-725, Arvin replaced the rear panel BNC

Jr to BNC connector with a special mini coax input at a right angle to

BNC output connector. This "low profile" fitting provided enough

clearance to then connect the exiting cable to J-14 which is the IF

Output on the Series 500 IF module.

To install the right-angle fitting requires a slight

enlarging of the mounting hole which Arvin apparently did by filing the

hole until the connector fit (I did check the junk main frame and it

showed evidence of filing.) The coaxial cable should be installed onto

the connector first. The center conductor of the coax is routed through

the right-angle tube and the shield is placed over the outside of the

tube. The center conductor is soldered to the center pin making sure the

teflon spacer is installed afterward. Then the crimping barrel is placed

over the shield and right-angle tube and crimped in place. Then the back

cover nut is installed. The BNC right-angle fitting with coax attached

can then be mounted to the rear panel of the receiver with a locking

washer and nut. Then the BNC Jr. end connector can be attached to J-14.

This completes the installation. Thanks to Moe CN8HD/W9 for supplying

the correct coaxial right-angle fitting (as mentioned, my coaxial

fitting was missing from my "junk" R-725 main frame.)

Testing the

R-725 - The R-725 mods were for a DF set-up (or for

Tropicom) so the

changes to the PTO tube, BFO tube and 3TF7 tube filament supply are very

subtle and not noticeable by just listening. However, the "big change,"

that is, adding the Series 500 IF module and thus eliminating the

mechanical filters and adding more IF stages,...that is very noticeable.

In fact, it's impressive! The gain is amazing. I have the Series 500 IF

gain set to 50% and the strong signals will still send the Carrier Level

meter to +80 or +90 db. If I tune off of the signal, the meter drops to

+10db. The selectivity is still very good. Just about as good as

mechanical filters. The R-725 has become my standard "vintage military

radio receiver" and it's set-up out in the shop with the T-368

transmitter and using a two half-waves in-phase

antenna,...aka, a 275ft center-fed dipole operated on 75M. The R-725 can always be counted on the "pull in" the

weak signals and

is easily able to cope with any QRM. Audio quality is good and sounds

pretty close to a typical R-390 receiver. Probably one could sum up the

R-725 as an "easier to work on R-390" with all of the benefits of the

R390 without as many headaches.

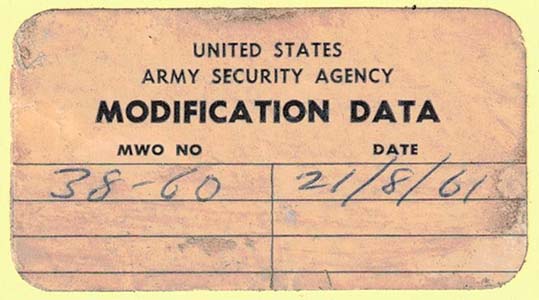

Wrap-up

- Well,...what is it? A restoration or a recreation? I was extremely

careful to use authentic R-725 parts harvested from a "destroyed,

incomplete" R-725. I was very careful to exactly duplicate how the

wiring harness was integrated into the R-390A harness. I even used the

original hum bucker harness for authenticity. Original R-725 sheet metal

was used where needed. Even the receiver used for the conversion was a

1967 EAC R-390A. The data plate used was an exact copy, etched tag -

not a silk screened tag but one made just like the originals. Even the

serial number stamped in the tag matches the serial number ink stamped

(in 1967) on the back of the Series 500 IF module. And, all of the R-725

parts came from the same "destroyed, incomplete" R-725 which must have

been the original SN: 74. So,...when looking over this R-725/URR,...I

consider it an authentic restoration of SN:74. Just that the original

R-725 SN:74 was modified in 1967 and my modification/restoration was performed in

2018. Close enough,...right? NOTE: I didn't write this

article in the journal format so there aren't any dates for the project.

But, fortunately, the photos are dated with the completed R-725 photos

being from March 2018.

|