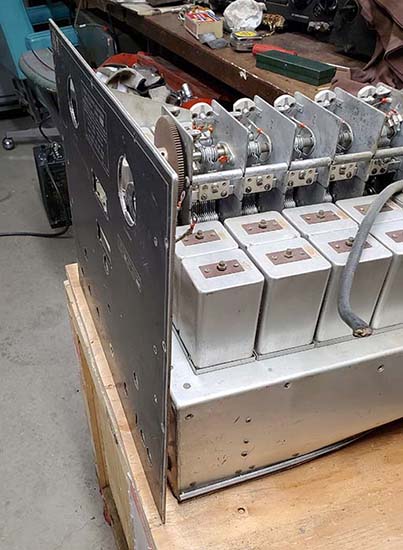

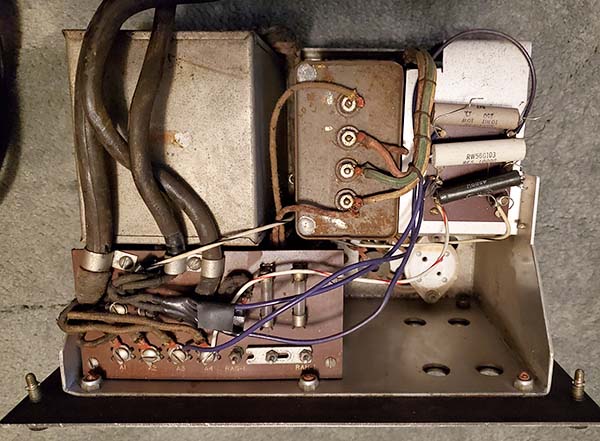

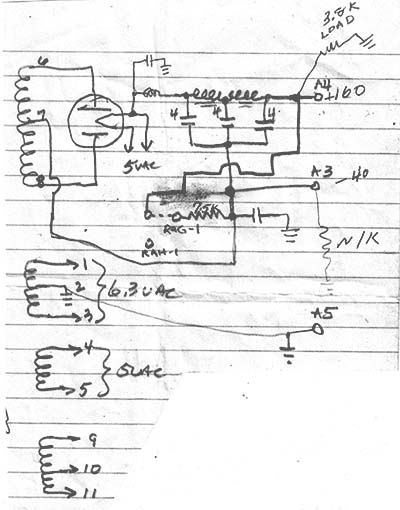

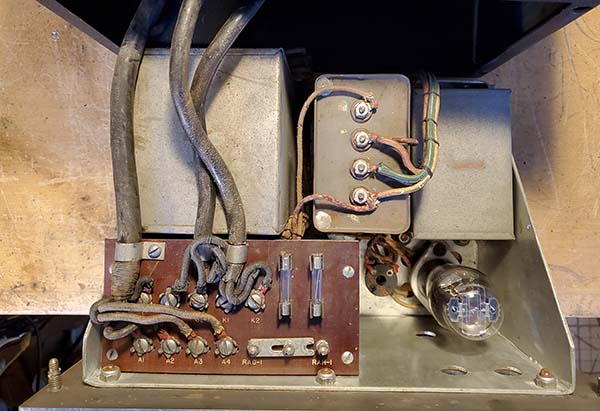

The RAG-1 was powered by a HP 712B power supply

providing 6.5vac tube heaters, +180vdc B+ and -55vdc bias. The

antenna was a 275' "T" wire antenna. Reproducers were 600Z ohm

earphones.

Daytime Test Reception:

VLF

NML - 25.2kc - LaMoure, ND - Very strong signal -

6.39 on RAG dial

NLK - 24.8kc - Jim Creek, WA - Extremely strong signal -

6.18 on RAG dial

NAA - 24.0kc - Cutler, ME - Strong signal - 5.88 on RAG dial

NPM - 21.4kc - Lualualei, HI - Very strong signal - 4.68 on

RAG dial

NWC - 19.8kc - Exmouth, Australia - very weak signal -

3.86 on RAG dial

All of these USN VLF MSK stations are very strong signals that are

easy to receive. NWC is a bit more difficult but is still receivable. They are transmitting almost 24/7. Good reception of these

stations in this particularly noisy region of the spectrum required the use

of the AUDIO TUNING which greatly reduces noise and enhances a specific

audio frequency that increases the MSK tones significantly above the

noise. A really great feature of the RAG-1 for VLF reception. AVC was ON

but set to about 5 which only limits very strong pulse-type noise.

Tuning range 1, SENSITIVITY 2

LF

WWVB - 60kc - Ft. Collins, CO - Very strong signal - 5.36

on RAG dial

JJY - 40kc - Mt. Otakadoya, Japan - Strong signal - 1.37 on RAG dial WWVB is easy to

receive anywhere in the USA at anytime. Again, AUDIO TUNING is able to

really enhance the pulse encoded signal of WWVB while greatly reducing

noise. Tuning range 2, SENSITIVITY 4. JJY 40kc (Japan's PE

Time Station) requires

listening mornings just before sunrise. Rcv'd 0545 hrs May 28, 2020. JJY

ID in Morse CW 15min and 45min after each hour. MW

MOG 404kc NDB - Montegue, CA - 5.64 on RAG dial

Daytime reception of MOG is difficult but the moderately weak strength signal was easily heard |

MW

Night Test Reception:

May 26, 2020 2150hrs to 2215hrs PDT

NDB STATION-FREQ-QTH

RAG DIAL

1. MOG 404kc - Montegue, CA -

5.64 ES

2. QQ 400kc - COMOX, BC, CAN - 5.59

3. ULS 395kc - Ulysses, KS -

5.51

4. PNA 392kc - Pinedale, WY -

5.42

5. YWB 389kc - West Bank, BC, CAN - 5.32

6. QV 385kc - Yorktown, SK, CAN - 5.23

7. CNP 383kc - Chappell, NE -

5.20

8. OEL 381kc - Oakley, KS -

5.13

9. GC 380kc - Gillette, WY -

5.08

10. EX 374kc - Kelowna, BC, CAN - 4.97

11. ZP 367kc - Queen Charlotte Is, BC, CAN - 4.79 ES

12. AA 365kc - Fargo, ND -

4.74

13. 6T 362kc - Foremost, AB, CAN - 4.66

14. NY 350kc - Enderby, BC, CAN - 4.33 ES

15. XX 344kc - Abbotsford, BC, CAN - 4.17 ES

16. RYN 338kc - Tucson, AZ -

3.98

17. DC 326kc - Princeton, BC, CAN - 3.62

ES

18. MA 326kc - Midland, TX -

3.62

Condx: Quiet,

occasional crashes, no wind, no weather fronts. Best reception for NDBs was with the AUDIO TUNING OFF, AVC ON and set

to 3 for the occasional crashes heard, Tuning Range 4, SENSITIVITY on 9.

18 NDB stations tuned in about 25 minutes. Stations marked "ES" were

extremely strong. All others were average signal strength and easy copy.

Best DX was probably QV 385kc in Saskatchewan and in the USA probably AA

365kc Fargo, ND or MA 326kc Midland, TX. Late May isn't the best time

for MW DXing but the RAG-1 performed quite well. I only tuned about 75kc

of the MW spectrum, that is, from about 325kc up to about 400kc. NDBs

can be found from 195kc up to about 425kc with a few around 515kc to

525kc. Listening at night between the Autumnal Equinox and the Vernal

Equinox results in much better reception conditions but, for late-May,

the RAG-1 did quite well. AM-BC

- Although many AM stations can be tuned on the RAG-1, its very

restricted audio renders voice transmissions almost incomprehensible and

music almost unlistenable. Additionally, the BFO is always ON. Tuning in AM stations is only for testing

purposes. |