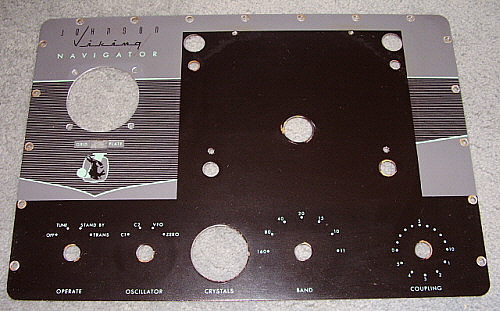

| Panel Touch-up - Dec 24,

2025

- I bought Testor's model paint in brown, gray and black, both in flat

and in gloss. I also had on hand blue, red, yellow, white and

green,...just in case. I was reasonably sure that the gray had a lot of

brown in it. The brown had a lot of black mixed in with it. The brown

was matched only using gloss brown and flat black. The mix of flat and

gloss gives the paint a matte finish which was like the original paint.

The gray was very difficult to match. It took gray, black and brown with

just one drop of blue. Luckily, most of the missing paint was located

where knobs or bezels would cover the touch-up. The "METER" nomenclature

was missing but I had the correct size dry-transfers but could only get

close on the font. Probably not noticeable at a casual glance. With

all of the knobs, the meter and the bezel mounted, the touch-up job is

pretty good. Certainly apparent if you know about the work that was done

but probably not noticeable unless pointed out.

Meter Problems - Dec 29, 2025- I

thought I was going to be using the same meter that had been in the Viking 1 before. I

tested it thoroughly and there's nothing wrong with the suspension and

the meter is fairly accurate. I suspect the problem is probably in the meter

switch soldering or the shunts. The wires are just pushed through the terminals and

soldered. With solid wire, there might be a cracked solder joint or

maybe one of the solid wires is cracked. Eventually, I ended up replacing this

meter with the one that I had tested (that had the cracked case) because

the latter meter was more linear over all.

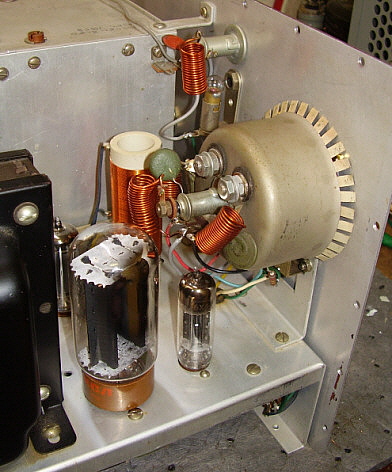

Plate Tuning Bezel, Index and

Rotating Scale Problems - Probably because the

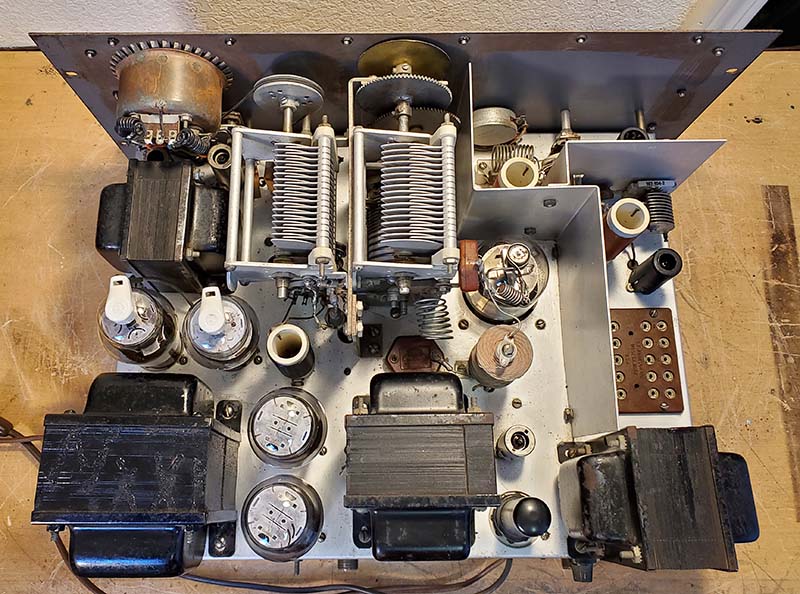

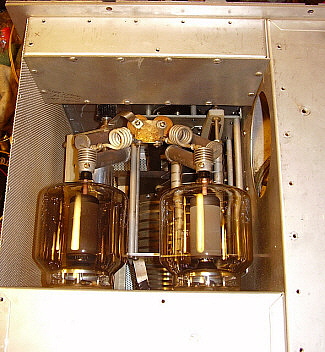

transmitter Pi-network was built using two different sets of parts,

nothing really fits together exactly. I actually find that the bezel

fits better and mates with the scales better if it's mounted upside

down. Not really noticeable unless it's pointed out.

Too Much Plate Current, too little Drive,

Other Issues - Dec 31, 2025

- I suspect that something is wrong with the shunt for Plate current.

For 100 watts output, the Plate I on the meter shows about 400mA. It

should be around 275mA. That should be with 12mA of grid drive but I

when set to 275mA Plate I, the drive is barely above 0 and the power

output is about 25 watts. I measured the

transmitter power supply voltages and found +630vdc plate voltage and +330vdc for screen voltage.

+LV measured +320vdc. Bias voltages measured -70vdc, -30vdc and -16vdc. All

of the voltages seemed to be correct.

Since the meter actually

measures a very low current across a low resistance shunt, if that shunt

has a higher resistance than expected, more current flows through the

meter resulting in a higher reading on the meter scale. It might be poor

soldering, it could be the shunts are too long (they are made of short

lengths of coiled wire) or maybe the chassis

ground isn't very conductive.

The problem ended up being poor soldering of

the shunts for both the Plate I and the Modulator I. Also, the ground

soldering on the shunts was very poor and the solder lug for the shunt

chassis ground wasn't tighten. I ended up removing the shunts

and moving the chassis-ground connection closer to the shunts location that only required about

a 1" wire to chassis. The shunt connections were cleaned and then the

shunts soldered back in place. I now had 110 watts RF Carrier output

power with 275mA of Plate I and the Drive was at 12mA grid current with

the Drive control set on about 4. This all looked correct. I switched to

MOD to measure the idling modulator Plate I and it was measuring about

30mA,...it should be between 60mA and 80mA. I readjusted the divider

resistor to slightly increase the screen voltage and that got the modulator

Plate I up to 70mA with +350vdc screen voltage, which is correct. I had to redo the solder on the

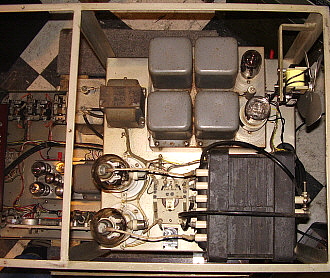

divider resistor terminals also. In fact, the entire transmitter looks

like it was assembled poorly with wire leads just pushed through

terminals and then soldered. No wire wraps at all. The soldering looks

like really cheap solder was used. Certainly not Kester 60/40 SnPb,...maybe just a

soldering iron that was too cold. Fortunately, by now, with all of the

rework that's happened over the past 17 years, most of the solder joints have been

corrected,...hopefully. Another Error

- In looking over the schematic, I happened to check over the bias

divider network and noticed that I had connected a 2.7K resistor in

parallel with the 1.5kc resistor to lower the bias on the modulator

tubes to -30vdc. I decided to just rebuild this divider network so the

bias voltages would be correct. I ended up removing the ground

lug that was tightened and redoing the divider network chassis ground

connection. I replaced the out-of-tolerance 1.5K resistor using an A-B

1.5K 2W 5% CC resistor. The bias voltages are now -77vdc, -33vdc and -22vdc

which should be close enough. I ended up entirely removing the 20K

100W WW adjustable voltage divider for the screen voltage adjustment since it was poorly

soldered and any adjustment of the slider seemed to not make contact. I

thoroughly cleaned the resistor, removed the rust from the inside of the

slider, remounted the resistor and soldered the wires to the terminals.

Now I had, +320vdc screen voltage and +600vdc plate voltage. Which looks

very close to the specified voltages. BUT, when measuring the Modulator

idling current it indicates about 40mA. It should be between 70mA and

90mA but that would require either lowering the modulator grid bias for

which there's no adjustment. Or, the modulator screen voltage could be

increased. The manual indicates about +280vdc modulator screen voltage

under load but the schematic indicates +300vdc. With the screen voltage that low the idling current would be

even lower than it already is.

Correct Voltage Dilemma

- So, what's correct,...the Johnson schematic, the Johnson manual or the

RCA tube manual? None of these documents agree on expected voltages or

currents. I had to slightly change the resistor values in the bias

network to have -74vdc which is the bias rectifier output and can't be

easily changed. Then I set the modulator grid bias for -30vdc which is

the tube manual spec if the plate voltage is +600vdc and the screen

voltage is +300vdc. I had to set the 20K divider quite different from

where it had been set since the screen voltage had been running about

+380vdc and +300vdc is maximum screen voltage rating for the 807s. The

bias voltage for the buffer tube is -17vdc which seems to be fine. The

Viking 1 manual says to adjust the 20K divider for 70mA to 90mA of

modulator idle current but that would require the screen voltage to be

set to about +400vdc! With ALL of the 807 voltages very close to the RCA

tube manual specs for a P-P 807 modulator, I get 40mA of idle current.

That is, with +290vdc screen voltage, +610vdc plate voltage and -30vdc

grid bias voltage. I double-checked the idle current by pulling one end

of the shunt and inserting a Triplett 630 to measure the current,...it

measured 35mA, so the Viking 1 panel meter is fairly close. Running into

the Collinear Array at a 1:1 match, I have 275mA of plate current with

12mA of grid drive. The power output is 110 watts on 3.974mc. The

modulator idle current is 40mA. The audio has never sounded better and

watching the 'scope pattern I can see lots of excellent positive peaks

and negative cut-off happening fairly often. My thought is that Johnson

was providing a kit and they wanted to make sure assembly didn't require

in-depth measurements and certainly not any hand-selecting component

values,...even though the expected builders would have been hams. The Aluminum Cabinet

- The two lower front panel mounting threaded holes were stripped and the

holes enlarged too much to really do any type of repair. I tried installing clip nuts

but the type I have (standard size 10-32) puts the hole too far inwards

for the front panel holes to align. Clip nuts are the best solution

so I had to modify the cabinet's mounting lip to allow the clip nuts to set

outwards about 1/8" which then would have the hole align with the

front panel holes. First, the 10-32 holes that were stripped and the two

that weren't stripped had to be drilled out to 5/16" for the clip nut to

seat correctly. Then I had to use a file to

recess the mounting lip edge with about an 1/8" notch that would allow

the clip nuts to seat correctly and align with the front panel holes. I

used the old Viking 1 TVI front panel as a template to make sure the

holes were in alignment. The four panel mounting holes now have clip

nuts installed which then allows the front panel of the transmitter to

be tightened up securely. Since the clip nuts have an actual steel nut

behind the clip the front panel screws can be tighten as needed.

Still More Problems -

When the Viking 1 was installed into the cabinet and connected to the

station antenna with the waveform monitored on an oscilloscope, the

transmitter wave envelope was at the expected amplitude initially. After

a few seconds to maybe a minute, the waveform amplitude suddenly dropped on the 'scope but the watt meter still

showed 100 watts output. SWR changes slightly but can be adjusted to a

null using the Matchbox. Still, the waveform amplitude on the 'scope

showed greatly reduced amplitude (peak to peak) but the watt meter showed

100 watts carrier power. Using a different transmitter but the same T-R relay, same

coax from the T-R relay to the Matchbox, no problems were encountered.

Interestingly, I listened the Wavelength Radio recording of the net so I

could hear what the Viking 1 transmission sounded like,...I didn't hear

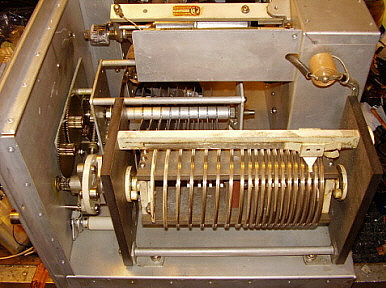

anything. I think there's a problem in the Pi-network or maybe the plate

blocking capacitor. It looks good on the plate current meter but

apparently the actual signal isn't getting through the Pi-network. As to

why the watt meter shows 100 watts when there's no output,...most watt

meters are only accurate when the SWR on the line is 1:1 and as the

mismatch increases so does the indicated RF output power. It might be

that the Pi-network problems are causing the erroneous watt meter

indications.

Nothing obvious was found

- The plate blocking capacitor tested good but the mounting was very

loose. It uses a "L" bracket mounted on one of the studs of the

frame of the roller inductor in the Pi-network. The bracket had to be dismounted to tighten

the capacitor screw (which was why it hadn't ever been tightened before.) I

also soldered the bias network resistors again. I also replaced the 6AL5

bias rectifier because one of the diodes tested low. I tested the

transmitter chassis on the

work bench by running a 50ft length of RG-58 from the bench over to the

ham shack to connect to the antenna. Everything looked good. I moved the

transmitter chassis into the ham shack and connected up everything

again. I made sure I was going through the T-R relay. Once again,

everything looked fine on the oscilloscope with 105 watts carrier power

indicating on the watt meter. I'm going to test multiple times in this

configuration before I put the Viking 1 back into it cabinet.

Jan 13, 2026 - Testing

consisted of three sessions, each session had the Viking 1 chassis

powered up for about 45 minutes and, during that time, three different

times a signal was transmitted via the Collinear Array at 105 watts of

carrier power, fully modulated. Each test transmission was about 30

seconds to 1 minute duration. Waveform monitoring was using the FNIRSI

oscilloscope. A total of nine transmissions were made. No problems

during any of the transmissions. |