|

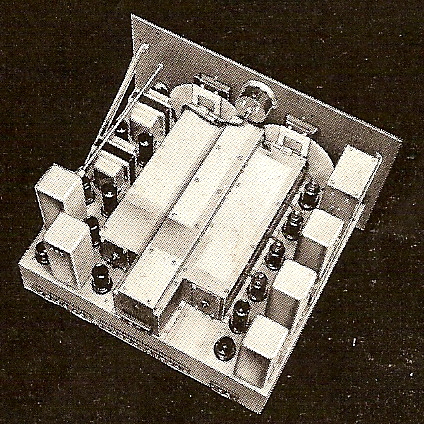

All of the various power supplies that were built for the Super-Pro

are similar in design and similar in the voltages provided to the

various models of Super-Pro receivers. There were three levels of B+,

+385vdc, +270vdc and +140vdc that were specified for the SP-200 series.

The tube heater supply is 6.3vac and the C bias is -50vdc. The early

receivers, the SP-10 and the SP-100 used power supplies that provide

slightly lower B+ voltages with +365vdc, + 260vdc and +110vdc indicated

in the manuals. The bias voltage isn't specified in these earlier

manuals but it is in the range of -45vdc to -50vdc. All of the various

types of power supplies route the voltages to the receiver through a

four foot cable that has a ten spade lug connector that screws to the

ten pin terminal strips on both the power supply and the rear of the

receiver chassis. Usually the metal box, protective covers that mount

over the terminal strips on both the power supply and the receiver

chassis will be missing.

The SP-10 power supply used a type 1-V rectifier tube for the bias

supply. This tube was replaced in the SP-100 supply with a type 80

rectifier tube. The HV rectifier was a 5Z3 until about 1944. Late power

supplies will use a 5U4G and a 5Y3G rectifier tubes. Early power supplies

used with the SP-10 and SP-100 will have a small second

terminal strip with two screw connections marked "Field" for the electrodynamic

speaker that was provided with these receivers. With

some late SP-100 and all of the SP-200 power supplies, a large choke

with a DCR of 1100 ohms was included in the power supply to replace the

field coil of the electrodynamic speaker and allow the use of a PM

speaker. The standard power supply had

a metal box cover with louvers that protected the tubes. The power

supplies were usually placed on the floor near the

receiver. Rack mount power supplies have a 19" panel screw mounted to

the front of the chassis and a metal cover over the top of the chassis

with lugs the protrude out the front panel for the cap nuts. Bottom

covers were standard on all types of power supplies. Metal cup, felt

center feet are usually mounted at the corners of the bottom cover for

non-rack units. Some rack mount units will have the felt feet included.

|

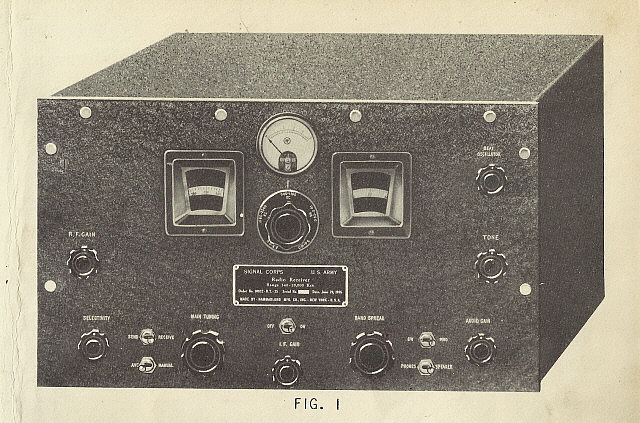

SP-100 PS SN:3388 - Note the two terminals for the field coil of

the electrodynamic speaker |

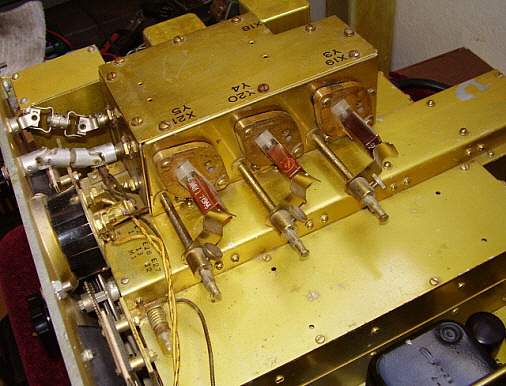

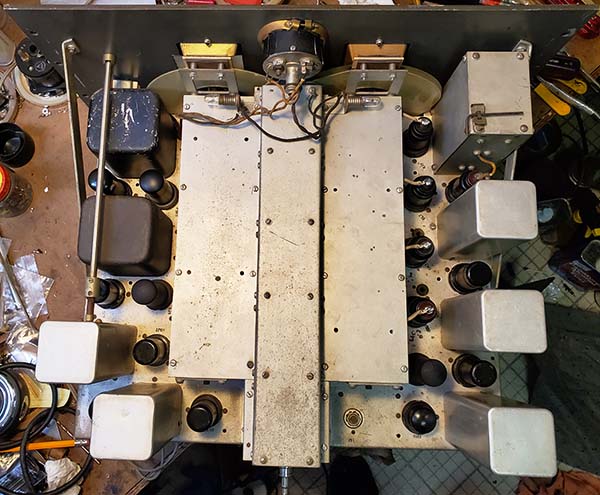

photo above: SP-200 PS Rack Mount - Note that the

terminals for the speaker field coil have been eliminated |

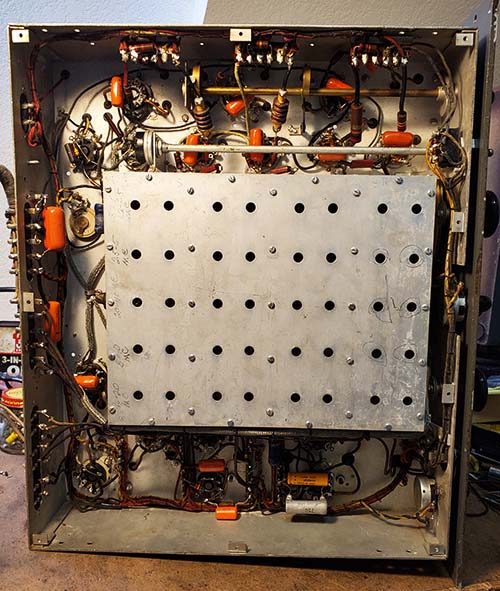

photo above: ASP-84B PS Military Rack Mount |

| Most of the military Super-Pro power supplies will have

an oversize potted power transformer and potted chokes with oil-filled

filter capacitors. Some of the late-version military supplies went to

can-type oil-filled paper capacitors. About this time the rectifiers were

changed to a 5U4G and a 5Y3G. All of the military supplies were normally

expected to operate in continuous duty service so the size of the power

transformer was substantially increased. Some of the military

power supplies will have dual primary power transformers for 115vac or

230vac operation. Military power supplies for the Signal Corps are

usually identified as RA-74, RA-84 or RA-94. RA-84 is for 115vac

operation only. The RA-74 is a heavy duty, multiple primary power supply and the RA-94 is

the heavy duty, dual primary power supply.

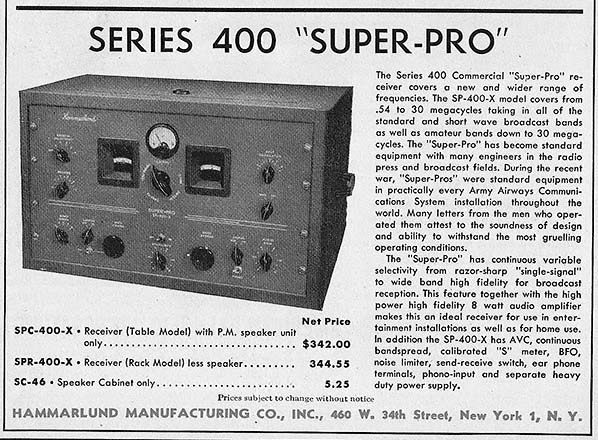

The SP-400 power supply is very similar to the non-military

versions of the SP-200 power supplies. Rectifiers used were the

5U4G and the 5Y3GT. Frame transformers and chokes are used.

Electrolytic filter capacitors are used. Output terminals and

power cable were not changed. Fortunately, almost any of the Super-Pro power supplies can

be used with almost any Super-Pro receiver. Considerations would

have to be made for the field coil connection on early supplies

but the voltage output terminals and the voltages present are

nearly the same for all power supplies and receivers. Care

should be taken when using a SP-200 power supply with either the

SP-10 or SP-100. The tubes used in the audio of the SP-10 are

42s and the SP-100 uses 6F6 tubes. The maximum plate voltage is

+375vdc on either type of tube. The SP-200 also used 6F6 tubes

and ran +385vdc at the connection terminals and assumed +380vdc

at the tube. But, the tube's maximum plate voltage is referenced to the

cathode voltage which is around +15vdc and that implies that the

plate-to-cathode voltage is around +365vdc which is fine. The

750 ohm cathode resistor didn't change in value in any of the

series so the increase from +365vdc in the early power supplies

to +385vdc in the SP-200 supplies was

probably viewed as a "safe" increase that resulted in slightly

more audio power. You can use a SP-200 power supply for testing

the SP-10 or SP-100 but for long-term operation of either type

of receiver, the correct power supply should be used. However,

it's

easy to modify a SP-200 supply by adding a 220 ohm 5 watt series

resistor in the +385vdc line to provide slightly lower Audio

Plate B+

voltage. The advantage

of always using a modified later power supply with either the SP-10 or SP-100 is

the elimination of the electrodynamic speaker requirement. These earlier

supplies utilized the field coil of the speaker as a filter

choke but later power supplies already have a choke installed so

a permanent magnet speaker can be used. The SP-200 power supply

can be used to power a SP-400 receiver with no modifications. |

|

Unfortunately, since just about any Super-Pro power

supply can be used with just about any Super-Pro receiver, very few

matched set-ups are found today - that is the sequentially serialized

receiver/power supply. With the SP-10 and SP-100 receivers, the original

power supply serial number is one off from the receiver serial

number. The assignment of a sequentially serialized power supply to a

specific receiver ended by the time the SP-200 was introduced in 1939.

The Super-Pro power cables normally encountered are

usually a nine wire, cloth covered cable with a special, spade-lug type

terminal strip connector on each end. These cables were used on the

later SP-200s and the military receivers. Some military power cables are

shielded and have rubber jacket insulation. Later nine wire SP-200

cables have tube heater wires that are of a larger gauge wire than the

remaining seven wires. The tenth lug is not used on these terminal

strips. On early cables, there are usually nine wires that are all the

same gauge. If a tenth wire is present, it is "switched to ground

(chassis) connection" that operates with the ON-OFF switch. It is not

used in the circuit as supplied but was provided as a spare function for

possible user applications. The switched ground operation is on most

Super-Pro receivers but the actual wire in the cable is seldom present

unless added by a former user. Many Super-Pros will be missing their

original power cable but the cables are easy to make. Just observe that

the tube heater connections, pins 1 and 2, use about 12 to14 gauge wires

while the remaining wires can be 16 to 18 gauge. The cable length is

approximately four feet. The connections to the

power supply match the receiver, 1 to 1, 2 to 2, etc. It isn't necessary

to have the terminal strip connectors but they do make connecting and

disconnecting the receiver and power supply much easier. The correct

orientation for an original power cable is to have the spade lugs

pointing down and the cable to exit the protective cover on the right

side.

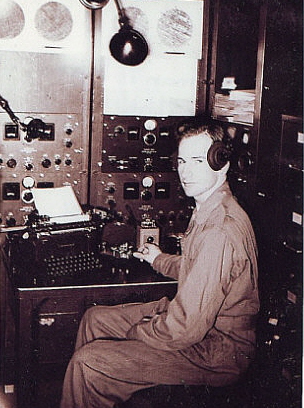

photo right: The power cable from a military SP-200

Series Super-Pro receiver-power supply showing the unique spade-lug type

connector strip

|

|

|

Hammarlund Super-Pro Serial Numbers and Estimated Production |

|

From examining many pre-WWII Super-Pro receivers along

with several HQ-120X receivers and Comet-Pro receivers, it appears that

Hammarlund issued serial numbers in a new sequence starting with "1" (or

some low number) beginning with the first SP-10 receiver and continuing

in sequence right through the military versions built during WWII. Since

the earlier Comet Pro receivers all have much higher serial numbers and

were all built before any Super-Pro receivers, they must have been

issued numbers from a different, earlier sequence. For example, a 1933

Comet Pro receiver with the SN: 7822 and a 1936 SP-10 with SN:576. It is

likely that all Hammarlund products that were going to be issued a

serial number were issued numbers from a common serial number roster.

Therefore all Super-Pro receivers were serialized sequentially as they

came off the line. It also appears that when the numbers were issued to

a Super-Pro "set," that receiver's power supply was issued the next

sequence number after the receiver's serial number. This is the case in

the two early matched sets that I know of. One is an SP-10, sn 720 and

PS sn 721. The second receiver, an SP-100X, sn 3387 and PS sn 3388. If

this was the normal Hammarlund practice, then each Super-Pro "set"

accounted for will use two numbers from the sequence - one for the

receiver and one for the power supply. There seems to be some SP-10 and

SP-100 sets that are "matched units" but are not sequential serial

numbers. The numbers are very close but not sequential. It was probably

standard procedure that a Super-Pro ordered from the factory would be

sent out with its sequentially numbered power supply. However, if one of

the many dealers got in a shipment of Super-Pro receivers and power

supplies, he might not be so careful to assure that a "matched" set be

provided to the purchaser. The matching of receiver and power supply

serial numbers accounting for the use of two sequential numbers from the

roster would hold true up to the time that the HQ-120X was introduced in

late 1938. It appears that the HQ-120X used the same serial number

roster as the Super-Pro "sets." After late 1938, the serial number

roster is split-up by Super-Pro receivers, SP Power Supplies and HQ-120X

receivers. By the time Hammarlund introduced the SP-200, the power

supply serial numbers were no longer sequentially assigned. When

Hammarlund starting to supply Super-Pros for the war effort (probably to

expedite production) no effort was taken to assure that certain power

supplies went with specific receivers. It is probable that specific

blocks of numbers from the roster were used for receivers and a

sequential block used for power supplies. This seems to be confirmed by

Super-Pro ASP-1004 SN: 27942 with matching power supply ASP-84B SN:

28870. A second ASP-84 serial number reported seems to be too early at

9686 but it may imply that the ASP SNs are a specific roster of numbers

(or the SN was reported incorrectly).

More ASP data will show whether this is the case. Speakers seem to have

an stamped-ink number but it appears that it may have been

identification numbers as sometimes different speakers are found with

the same numbers stamped inside. For now, we will assume that speakers

were not part of the serial number roster.

This use of sequential serial numbers issued to all

receiver products as they left the line makes estimating production

quantities very difficult. One has to take into account that lower

priced receivers, like the HQ-120X, sold in larger quantities than the

Super-Pro. Also, that the HQ-120X didn't appear until late 1938 and

therefore didn't affect the 1936 to 1938 Super-Pro serial numbers.

Additionally, the power supply serial number will divide the serial

number total by two for production totals for 1936 through most of 1938.

After the HQ-120X appears, a percentage must be factored into the serial

number total to extrapolate the Super-Pro production.

Without doubt, the SP-10 is a rare receiver. Very few

are ever encountered and from that one naturally concludes that

production was very low. It is likely that no more than 500 SP-10

receivers were built since it was only in production less than nine

months. With the SP-100, production goes from January 1937 up to about

August 1939, or about two years and eight months. Again though, the

SP-100 is rarely encountered. Production should be around 1000 receivers

because the HQ-120X has to be factored into the serial number use for

about the last year of SP-100 production. The SP-150 is so rare with

only 70 produced it is included with the SP-100 group. The pre-war

SP-200 is not a common receiver either. Probably only 1800 Super-Pro

SP-200 receivers were built before WWII began. With the WWII production,

the now commonly seen Super-Pro receivers are found. Production here was

around 10,000 receivers, perhaps more. Total Super-Pro production from

1936 up to 1945 should be around 14,000 receivers. Compare this to the

SX-28A production of around 11,000 receivers (not including SX-28

production) and a correlation can be seen as to how often any of the

pre-war and wartime Super-Pro receivers are seen versus how often an

SX-28A is encountered. The comparison seems valid.

One note,...the serial number on the military tag of all

BC Super-Pro receivers will not match the Hammarlund factory serial

number stamped on the rear of the chassis. The tag number was usually

assigned for the Signal Corps by Hammarlund for that receiver to be part

of a specific contract quantity. It will never match the chassis-stamped serial number

that was issued at the time of assembly. |

The following tables are rough estimates based

on serial numbers encountered weighed against quantity of receivers seen

and the assumed division of the serial number pool.

|

Serial Number Sequence with Estimated Production

Model

Serial Numbers Quantity Built

SP-10

Series....................1 up to ~1000........actual

receivers ~500

SP-100

Series..................1000 to ~4000.......actual receivers

~1200 (SNs shared with HQ-120X)

SP-200

Series (pre-war)...4000 to ~10000.....actual receivers ~1800

(SNs shared with HQ-120X)

SP-200

Military..............~10000 to 30000+....actual receivers ~

10000+

SP-400

Series.................... 4-0001 up to?....actual

receivers ?

|

Year to

Serial Number Table

SN Range

Year Models

1 to 1000 ........... 1936.......SP-10, PS

1000 to 3000.......1937.......SP-100, PS

3000 to 3800.......1938.......SP-100, PS,

HQ-120X

3800 to 5000.......1939.......SP-100, SP-200,

PS, HQ-120X

5000 to 8500........1940.......SP-200, PS,

HQ-120X

8500 to 10000......1941.......SP-200, PS,

HQ-120X

10000 to

14500......1942.......SP-200, BC series, PS, HQ-120X (RBG uses a

different format of SNs)

14500 to

19000......1943.......SP-200, BC series, PS

19000 to 25500......1944.......SP-200, BC series,

PS

25500 to

30000+....1945.......SP-200, BC series, PS |

|

|

Known Serial Number Log

This is a log of known and reported serial numbers for

all Hammarlund Super Pro receiver types made prior to the SP-600

receiver (Super-Pros from 1936 to 1948.) Also included are the SP power supplies

with "matched-pair" indicators where known. I've also included the HQ-120X

since it was serialized from the same number sequence as the Super-Pro

and those serial numbers do affect the total production quantity of

appropriate Super-Pro receivers. I've also included the military RBH/CHC-46140

out of curiosity. The Comet Pro receivers are included to show they were

serialized from a different sequence of numbers.

The

Super Pros are broken down into the various civilian models and the

three Signal Corps military versions. Likewise, the power supplies are

divided into civilian and military. Be sure to observe that the Signal

Corps tag on the front of the SP receiver has a Signal Corps serial

number and the receiver itself has a Hammarlund assigned serial number

stamped on the rear apron of the chassis. The Hammarlund assigned serial

number is what we are logging. Note that the SP-400 serial numbers are

using a different format with one digit, a hyphen followed by four

digits.

|

SP-10: 575, 576, 674(ps 804),

720(ps 721), 913, 979(ps 987), 1023, 1110,

SP-100: 1352*, 2562(ps 2612),

2564(ps 2615), 2570, 2672(SX), 2714,

2730(LX), 2746(ps 2785), 3356,

3387(ps 3388), 3417(ps 3400), 3665(LX-ps 3649) 3826,

4106(LX), 4475(LX),

SP-150: 3055(ps 3105),

SP-200X: 4121, 4227, 4239, 4833, 4912,

4955, 5580, 5658, 6005(ps 6056), 6045, 6239(ps 6215),

7060(SC), 7334, 7853, 8295, 9419, 10664, 14910(ps 15204), 16135,

SP-200SX: 4146, 4289, 5226, 6230, 6289(ps 6331),

9759, 15775(ps 14653)

SP-200LX: 6776, 6884, 6965, 7353, 7381, 7545, 8023,

8423, 8466, 9262

SP-200X - Special: - 5733, 5858,

BC-779 (incl. Howard:) 6530H, 6873H, 7416H,

9030H, 9828, 11162H, 12421, 23688, 25298 BC-794: 19828, BC-1004: 18320, 21009,

27942(ASP-1004),

R-129/U:

|

Super-Pro PS CIV: 3545(100), 4215B (200), 4287, 5164,

7036(200SC), 9238(200), 11184, 11865 Super-Pro PS MIL: 5514H (ASP-84), 9686(ASP-84), 17656(RA-94),

17783(RA-94), 21186(794), 22093(1004), 26595(RA-74),

28870(ASP-84)

HQ-120X: 7007, 7244, 7408, 7711, 9630,

9881,

RBG/CHC-46140: 519(RBG-2), 524(RBG-2), 982(RBG-2), 1473(RBG-2),

SP-400-X: 4-2683(ps 4-2200),

SP-400-SX: 4-1249(ps 4-1038), 4X2566,

Comet All Wave: 1006

Comet Pro: 7531, 7822, 8001, 8079 |

NOTE:

Sequential or close (matched-with receiver) serial numbered power

supplies are listed in () along with receiver SN

* = variation of standard model SP-10 or SP-100 (SP-200 listed as

Special)

(Howard) = BC-779 receivers built by Howard Radio Co. as a

contractor during WWII will have "H" suffix in serial number

(Howard also built BC-1004 receivers)

(Special) = SP-200 Receiver with special frequency coverage or

other non-standard features

(SC) = Signal Corps - military contract

model |

|

|

Super-Pro

Serial Numbers Needed

Since it appears that all Super-Pro receivers and their

power supplies along with the HQ-120X receivers were serialized from a

common serial number roster, any serial number from any of these

Hammarlund products provides important information as to production

quantity and date lines. Even the earlier Comet Pro serial numbers

should show that it used a different set of numbers. If you have one or

more pre-war Super-Pro receivers, SP power supplies, HQ-120X, RBG,

SP-400 or Comet

Pro receivers, please e-mail the serial number and what model it goes

with to Western Historic Radio Museum. I'm just starting to log

serial numbers (Aug2019) for the SP-400 receivers. The SP-400 serial

numbers use a different format but as

more SNs are logged it may show some connection to the earlier model

serial numbers. Be sure if your Super Pro

is a military version to send the Hammarlund serial number stamped on

the rear of the chassis not the serial number on the ID tag. We will

add the information to the Known Serial Number Log. With each number,

more knowledge is gained about these incredible receivers and that

information will be added to this website. Hopefully the result will be

an on-line accurate source of information about the pre-war Super-Pro

receivers.

e-mail Super-Pro info to:

WHRM-SUPER-PRO

SERIAL NUMBERS |

|