|

1935 - SPA (SP-10) - June 29, 1935 Order Number

10932-NY-35 issued for Hammarlund SPA Super-Pro Receiver for the Signal

Corps US Army. SPA is identical

to the SP-10 except for the

installation of a data plate on the front panel. It's likely that these

receivers were delivered before the official March 1936

introduction presented in QST

magazine that month.

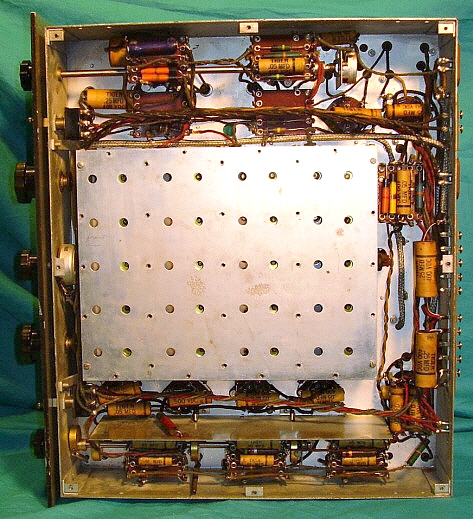

1936 - SP-10 - Uses all large-pin glass tubes,

has separate RF, IF and AF Gain controls along with Tone control, no

pointers on knobs

Variable coupling on Detector and AVC

transformers

Both audio transformers are potted units

Audio output transformer was probably an 8 ohm

Z output on all receivers

Resistors may have been added to create a 600 ohm output

Z on some receivers

Some receivers may have had a standard phone

jack audio output on front panel

Aluminum front panel .187" thickness, engraved

nomenclature

Paper-wax capacitors are usually Aerovox brand,

sometimes intermixed with Cornell-Dubilier brand

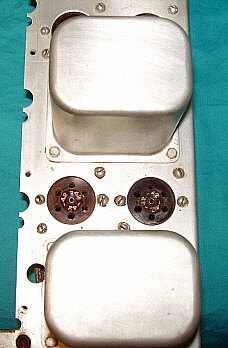

Spacing rods in RF tuning unit are

brass

Non-illuminated Tuning Meter measured total IF

amplifier current

S-version introduced in June 1936 tunes 1.2 to

40 MC

Bias series resistor string modified - 600 ohm

resistor replaced with 2-300 ohm, allowed moving detector input amp grid

connection

to junction which slightly increased bias

voltage

BFO Plate Load resistor changed from 5K to 50K

(may be parts list error as all known examples use 50K)

BFO Grid capacitor (100pf) changed from grid to

ground connection to parallel with grid leak resistor connection,

(possible schematic error)

Tone control eliminated in late production

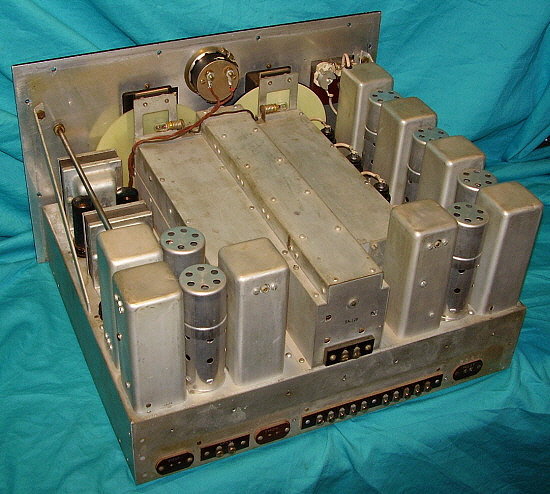

1937 - SP-100 - Introduced January 1937, uses eight metal octal

tubes and eight large-pin glass tubes, Sensitivity Control replaces

separate RF and IF gain controls,

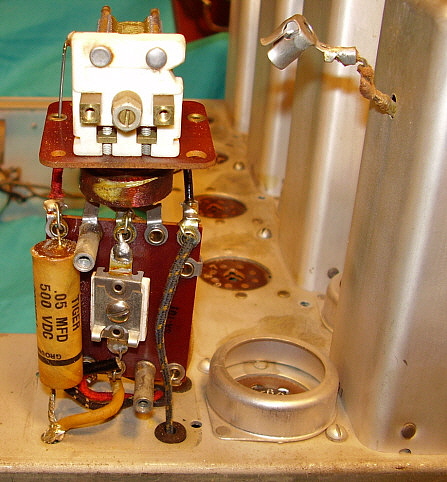

Variable coupling AVC and Detector

transformers changed to fixed coupling, Selectivity control renamed Band

Width, engraved scales added to

Sensitivity, Beat Oscillator, Band Width and

Audio Gain controls

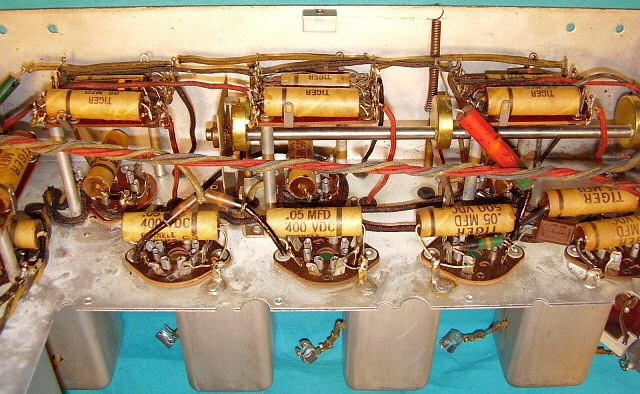

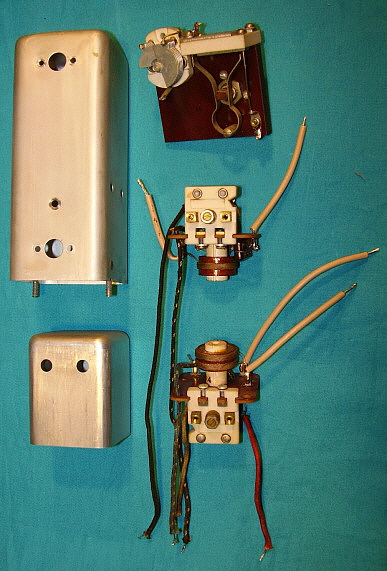

Fixed-coupled AVC and Detector transformers

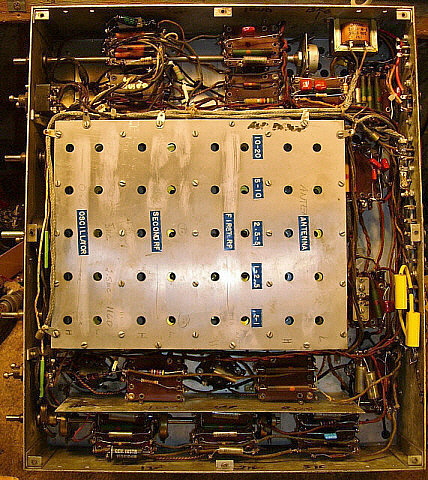

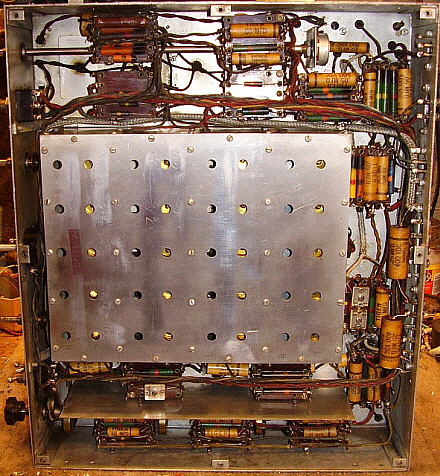

allowed the component boards to be moved from under the chassis (SP-10)

to inside the transformer cans (SP-100)

New style small knobs with metal

pointers

Audio transformers changed from potted units

to vertical mount-frame types - output Z is 8 ohms

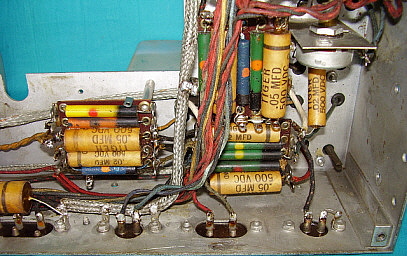

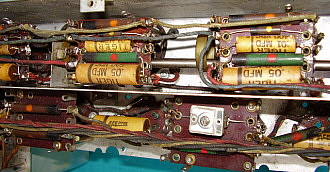

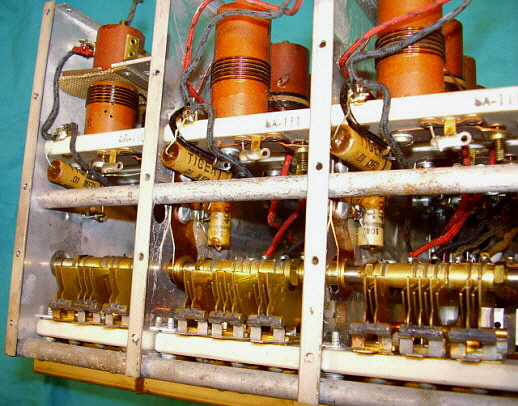

Paper-wax capacitors are usually

Cornell-Dubilier "TIGER" brand but could be intermixed with Aerovox

brand

Spacing rods in RF tuning unit are

steel

1938 - SP-100 - SP-100L introduced as low

frequency

version, 100KC-400KC and 2.5-20.0MC, production receivers have same

audio output configurations as the SP-100X.

Late

or Military versions of the "L" may have had front

panel "Phone" jack, dual secondary windings - 600Z speaker and Hi-Z

(8K) phones

"LX" version added a Crystal Filter

SP-150 console Super-Pro introduced in July

1938

1939 - SP-100 - SP-100 Crystal Filter - separate

smaller panel eliminated on last of series and CF mounted directly to

front panel

SP-200 introduced October 1939, added Noise

Limiter, Amplified AVC redesigned, Crystal Filter redesigned, IF section

redesigned

Illuminated S-meter replaced Tuning Meter

Over/under toggle switches replaced with

rotary switches with knobs, 18 tube circuit, larger power cable because

of

increased diameter of tube heater wires,

early SP-200 may use SP-100 frame type audio transformers

1940 - SP-200 - Front panel Speaker/Phones

switch changed to .25" phone jack, added dual secondary windings to

output transformer

allowed separate 600 ohm Z and Hi-Z ohm

earphone outputs on X and SX version. It is possible that LX version

already had this configuration.

Audio transformers now potted units.

1941 - SP-200 - Front Panel changed to .125"

thick steel with stamped engraving filled white, front panel paint

changed to semi-gloss black

Steel front panels are nickel-copper plated on

front side only as corrosion preventative

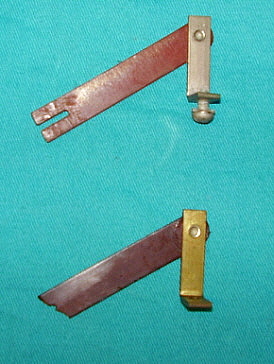

Spacers added to panel mountings because of

thickness difference

1942 - SP-200 - Probable beginning of Signal

Corps BC series - some receivers may have rubber stamped SC order

numbers indicating that it was purchased from civilian source.

Militarization of power supplies with heavy

duty parts

1943 - SP-200 - Painting of front panel changed

to red oxide primer coat with grayish paint, color of the panels is

highly variable with gray, blue-gray and green-gray commonly seen.

Tube layout charts are added to the top of the

RF box

Schematic added to inside of bottom cover of

the power supply

S-meter housing changed, full glass front

replaced with partial glass with zero adjust mounted in metal

TM-11-866 Signal Corps Manual, first version.

Manual covers BC-779, BC-794, BC-1004 and R-129/U plus power supplies

RA-74, RA-84 and RA-94

1944 - SP-200 - Probable year for contactor built

BC-779. Howard Radio seems to be the only company used as a contractor.

Howard also built BC-1004 receivers.

1945 - SP-200 - Late 1945 probable design

date for SP-400

Post -WWII - SP-400-X and

SP-400-SX models introduced in 1946. .54-30mc for X and 1.25-40mc for SX.

455kc IF for both versions, although "SX" version SN 4-1249 has a 465kc

IF. This suggests that perhaps

those receivers built early in production used WWII surplus Super-Pro

parts. When the 465kc IF parts exhausted, then the remaining SP-400s

were equipped with the new 455kc IF. Just speculation.

Other SP-400 changes are mostly cosmetic. No military contracts for

SP-400 receivers.

The Signal Corps continued to

support and use the SP-200 Super Pro receivers. Some of the MWOs and

manual additions date well into the 1950s.

Rectifiers changed in the RA-74D power

supply, 5U4 and 5Y3, also 12 cylindrical oil-filled paper capacitors

replace the two large block capacitors (1948)

Improvement Kit MC-531 shown in TM11-866 (Feb

1948 printing) - this is the three channel selectable crystal-controlled oscillator

upgrade

Wickes Engineering R-270/FRR receivers

supplied for AN/FRR-12 Dual Diversity Receivers - R-270 is a modified

BC-794 receiver (1948)

|