| 1936

NC-100 and NC-100X introduced in August 1936

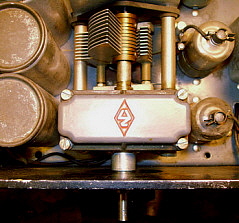

The Art Deco Panel - Aluminum sheet metal overlay for front panel is silk screened in

black and red along with silver - used on both NC-100 and NC-100X,

commonly referred to as the "Art Deco Panel." This panel was only used

from the initial run-D up through run-G on the NC-100 and NC-100X. A black wrinkle finish

overlay replaced the Art Deco panel and the eye tube was integrated in

the same manner as the NC-101X. The PW-D likely would have also been

changed to the black with black number dial, the same as the NC-101X. This change

probably happened during or just after run-G. Certainly, by run-J, the S-meter

replaced the eye-tube and then, at the very latest, the Art Deco panel was

gone for good. It was certainly not used after the replacement of the

eye-tube with the S-meter (run-J or mid-1937.) The Art Deco panel was

replaced for a couple of reasons. First, it was delicate and scratched

very easily. Excessive rubbing would easily wear through all of the

silk-screen artwork and would also wear the matte silver finish. The second

reason

was as an expense reduction by the consolidation of parts. The Art Deco panel was unique to

the NC-100 and NC-100X and certainly the process to produce the panel

(or have it produced)

was more expensive than a black wrinkle paint job. It was much easier

and less expensive for National to start using the NC-101X black wrinkle

overlay with these types of panels which were then usable on three types of receivers.

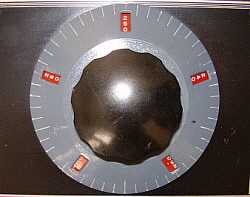

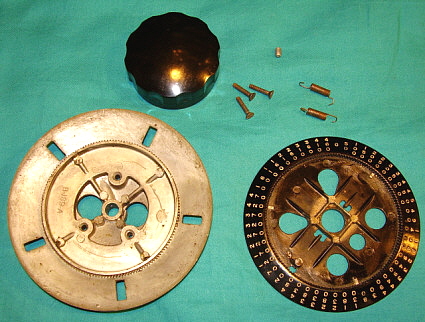

The PW-D - The initial PW-D micrometer dial used on early receivers was

bluish-gray on the Index Dial and red with white numbers on the Number

Dial, used on the NC-100 and possibly the very early versions of the NC-100X. Slight variations in PW-D

paint color might be due to color variations in different paint mixes or

due to different aging characteristics on specific PW-D dials. However,

many PW-D dials were replaced over the years by owners and careless

restorers so originality becomes uncertain. Generally, very early NC-100

receivers will have the bluish-gray Index Dial and red with white

numerals Number dial. The NC-100X will usually have a light-gray

Index dial with a black number dial with white numerals. There may be exceptions to this

but, from examples seen, this PW-D difference between the NC-100 and the

NC-100X seems to be consistent. Photo of 638-G (eBay) had deco panel and

light gray PW-D with black number dial with white numerals - looked

original. Also, NC-100X sn:48E, an original example, has a gray Index dial with a black

Number dial. I don't have any data collected on whether the red number

dial was used in the PW-D for the NC-100 past the first production run.

Please report any NC-100 receivers in the E, F or G runs that have been

found with original red number dial PW-D.

Chassis is painted gray on both NC-100 and NC-100X

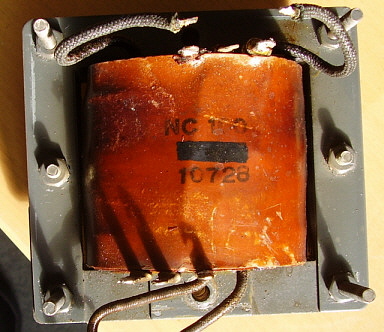

Power transformer top cover has four large ventilation holes

6E5 cathode ray tuning eye tube is used

Rack mount versions will not have aluminum overlay, panel is 3/16"

aluminum with engraved markings, black wrinkle finish, eye tube used.

Some versions may have single-ended audio output. Some rack mounted

versions will use National-supplied rack mounting brackets that mount to

the sides of the standard NC-100 table cabinet.

The first NC-100 and NC-100X receivers were built in production run

"D"

The NC-100 was the first National Co. receiver to utilize an

electrodynamic loudspeaker that had its field coil powered by the

receiver's power supply. Although there were some SW-5 versions that had

push-pull audio output, these receivers had to utilize a "self-powered"

electrodynamic loudspeaker. These speakers had an onboard power supply

just for the field coil and they were popular in the late-twenties and

early-thirties.

NC-101X is introduced with ham band only coverage, black PW-D on most

of production, eye tube on early versions (NC-101X introduced during "E"

production run, probably Oct-Nov 1936)

1937

Contracts for Airport "Communication Receiver" from Dept. of

Commerce, Bureau of Air Commerce Air Navigation Division. DOC-BAC

receivers are the RCD and RCE

S-meter replaced eye-tube in NC-101X - changeover to S-meter seems to

have occurred between runs J to L (runs six, seven or eight, or around

mid-1937.) Some earlier NC-101X receivers seem to have been modified to

replace the eye tube with an S-meter. Some of these upgrades were

obviously rework performed at National and exhibit professional-level

installations. Others appear to be "hamster" modifications. For example,

NC-101X sn 247-J is a sixth production run receiver but has the later

Marion Electric yellow scale S-meter installed instead of an eye-tube or

the earlier white face Marion Electric meter. Since some hams sent their

receivers to National for repairs or upgrades, it's possible that early

production run receivers that have yellow scale S-meters may have been

replacements that were installed by National during a repair. It's also

possible that late-style replacement S-meters were obtained from

National were installed by receiver owners. In general, on original

receivers that haven't been reworked, expect to see the white face

S-meters from around run J up to around run N. The yellow face S-meter

should be installed on receivers from around run P up to around run Y

(probably early-1938 up to 1940.) This change also affected the NC-100

and NC-100X and (at the very latest) eliminated the "Art Deco" overlay on

those receivers.

Power transformer top cover vent holes eliminated

Installation of the S-meter switch eliminated the green pilot lamp so

all S-meters were illuminated to provide a "power on" indicator. All

stock S-meters were manufactured by Marion Electric.

NC-80X and NC-81X AC-DC receivers introduced. Optional power

transformer available to convert to AC-only operation. Also a

battery-operated version was available.

1938

NC-100A and NC-100XA introduced in June 1938. New direct-read dial,

articulated pointer, illuminated S-meter, cabinet height increased to

10.5", weighted tuning knob on early versions. White face S-meter used

on earliest production. The transition to the yellow face meter probably

coincides with the NC-101X meter change around run-P.

Contracts for "Airway Communication Receivers" begin - the U.S. Civil

Aeronautics Authority, the CAA, was formed in 1938. CAA receivers begin

with the RCF-2 version. All Airport and Airway receivers use a PW-D with

a light gray color Index dial and a black Number Dial with white

numerals. This light gray color Index dial is quite different than the

bluish-gray Index dial used on the earlier NC-100 PW-D.

NC-101XA introduced. Both versions (direct read dial or PW-D

micrometer dial) are available up around mid-1940.

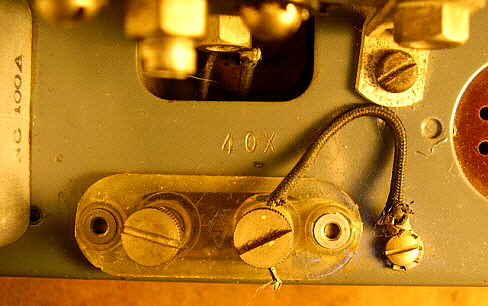

Some models will be found with fiber board, blade screw terminals

Antenna and Ground connections. These probably replaced the

problem-prone push button terminals found on earlier models. This piece

was the transition part that then led to the polystyrene insulated

Antenna and Ground terminals with thumb screw fasteners.

1939

Noise Limiter circuit added to NC-100A versions. 6F8G (1stAF/AVC Amp)

and 6C8G (Detector/NL) replaced the 6C5 (Detector) and 6J7 (AVC Amp)

tubes. The Noise Limiter was also incorporated into the NC-101X

receivers along with the tube changes. NL available November 1939. On

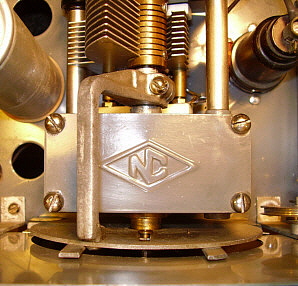

NC-101X with NL, the control is between the RF Gain and the Band Change

knob where the National NC diamond logo was engraved. The "NC" diamond

logo is relocated on these NL receivers to the upper right corner of the

front panel.

By late-1939, NC-101X receivers will use NC-100XA chassis but are

built as NC-101X receivers. That is, all holes needed for the "A"

direct-read dial are present on the NC-101X chassis although not needed

or used. Usually, one side of the chassis will have "101-X" written in

orange grease pencil to ID chassis so assemblers know not to install the

"A" dial and "A" gear box.

NC-80X and NC-81X not produced after 1939. NC-80X cut-off may be

1938. Neither receiver sold well and examples are rarely encountered

today.

1940

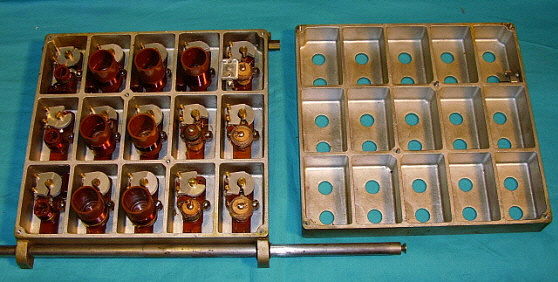

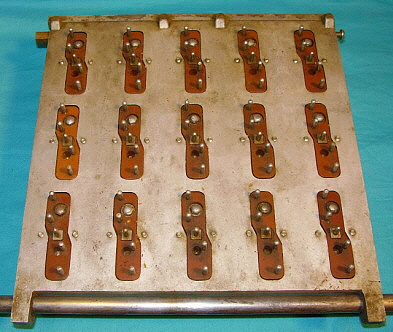

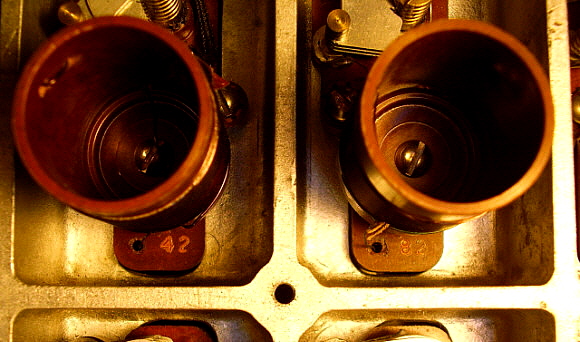

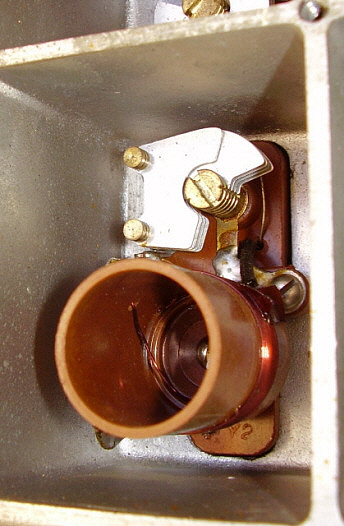

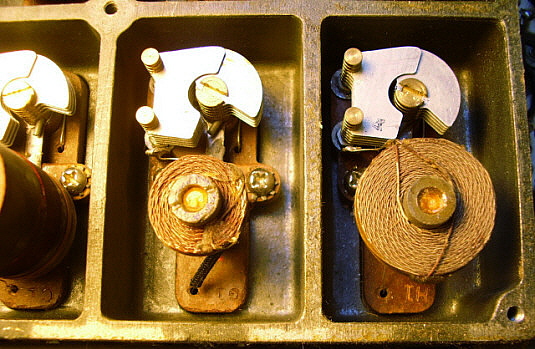

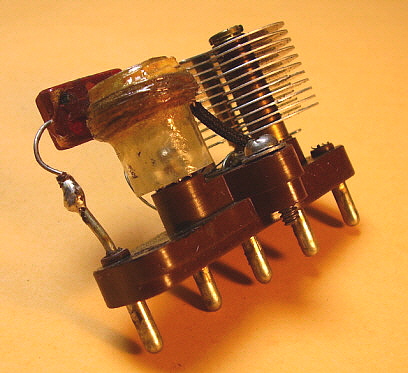

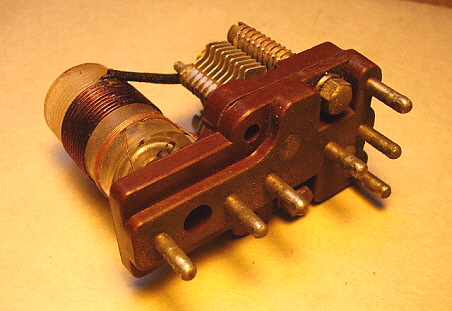

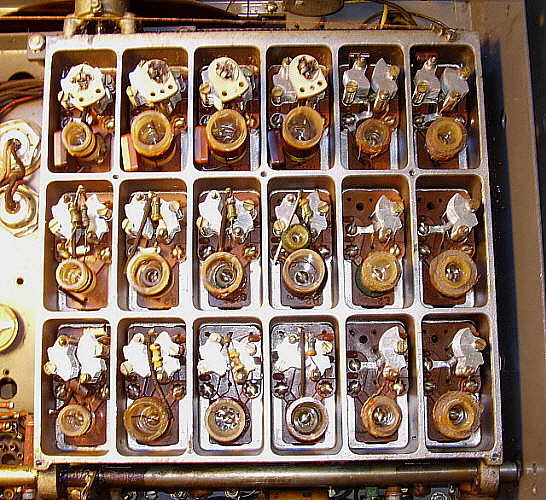

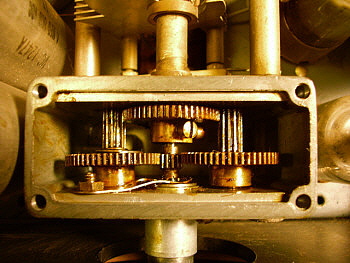

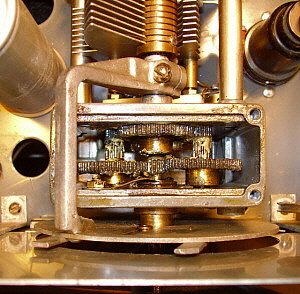

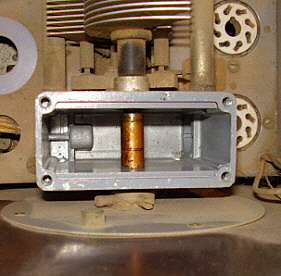

Tuning condenser design changed to replace large bakelite insulator

plates with smaller round insulators, thin metal dividers replaced with

thicker metal dividers that now support the rotor contact insulators,

rotor plate hub changed from brass to steel, support rods dimensions

reduced, two screw rear mounting flange. Cost reduction? HRO tuning

condenser went through similar changes.

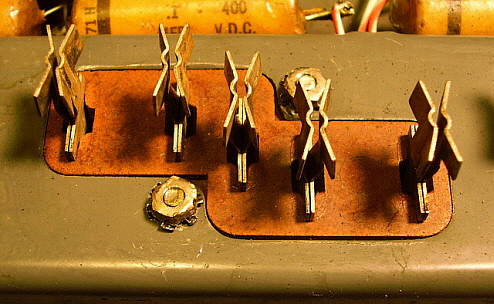

Antenna/Ground thumb-screw terminals with Polystyrene insulator

replaces the old "push terminals" with fiber board insulator or the

fiber board, screw terminals found on some models.

NC-101X production stops before May 1940. The direct-read dial

version - NC-101XA - production may have continued until the NC-200 was

incorporated into production (Sept-Oct.)

When the two-screw rear mounting flange was used on the tuning

condenser, the serial number location had to be moved to the left side

of the antenna terminal insulator (nearer to the audio output tubes.)

NC-200 introduced (October) - features both general coverage and band

spread coils within the catacomb thus eliminating the need for separate

"ham bands only" receivers like the NC-101X or NC-101XA.

NC-200 Crystal Filter changed from variable condenser Selectivity

control to six-position switch with five selectivity positions and "off"

position. Crystal at 455kc to match new IF frequency.

LO tube changed to a 6J5 triode in NC-200 Series. Many other tube

changes in the NC-200, see tube line up in section below "Vacuum Tubes

Used in All NC-100 and NC-200 Series Receivers."

Dec. 1940 QST ad for "Silver Anniversary" NC-200. Special NC diamond

insignia on receiver and matching speaker. Also, receiver equipped with

brown knobs and brown S-meter case. All round control nomenclature

plates, the tuning knob's skirt and the Silver Anniversary NC diamonds

are finished in "gold tone." The Silver Anniversary NC-200 celebrated

QST's 25th year and wasn't associated with any National anniversary.

Silver Anniversary models start as early as C-33 and run until as late

as D-639. NC-200 receivers D-700 and D-716 are both standard NC-200

receivers indicating that the Silver Anniversary ended by D-700.

NC-200 early versions will have a flat dial cover that is glass

(similar to the NC-100A versions.) Some early NC-200 receivers had

plexiglass as the dial cover. Other early NC-200 receiver used the

vacuum-molded plastic dial cover but it was mounted using clamps located

on the inside of the front panel. Later versions of the NC-200 will have

the slightly convex vacuum-molded plastic dial cover that is mounted

with two exterior metal strips held to the panel with screws.

1941-45

RAO USN versions - RAO, RAO-1,2,6,7 & 9 built by National, RAO-3,4 &

5 built by Wells Gardner & Company. RAO-2 through 9 have double preselection. All

versions have .54mc to 30mc coverage. Early versions have 500 Z ohm

audio outputs, RAO 7 & 9 have 600 Z ohm audio output. RAO-2 thru 6 are

17.5" wide, RAO-7 & 9 are 19" wide. RAO-6, 7 & 9 don't have S-meters

installed but have an output for panadaptor use instead. First 200 RAO-6

receivers were equipped with S-meters but the remaining production had

the panadaptor set-up. RAO-7 & 9 have

unique molded skirt bar knobs. Gears used in the later gearboxes are

changed from brass gears to cast pot metal gears for wartime material

conservation. Late gearboxes have an added idler gear with mechanical

stops to limit the total main tuning shaft revolutions to slightly over

ten turns. The double pre-selection design upgrade with the add-on

chassis, coil box and sheet metal cabinet pieces certainly pre-dates

WWII and may have been available to USN as early as mid-1941. As an

example, the R-116 USCG receiver from a May 15, 1941 contract has dual

preselection incorporated identically to the RAO-2 receiver although the

receiver itself has significant differences in front panel layout,

mechanical design, frequency coverage and tubes used. Also, utilizes a

separate power source (AC power supply, batteries or other shipboard

power source.)

RBH USN version of NC-100XA with special frequency coverage of 300kc

to 1200kc and 1700kc to 17.0mc, IF changed to 1500kc, single ended

audio, 500 Z ohm output. Later versions, starting with RBH-1,

added an extra RF amplifier similar to the RAO and for similar reasons.

It's likely that the RBH series follows the same evolution that the RAO

did.

NC-100ASD Signal Corps version, ca: 1943 - replaced AM BC coverage

with 200kc to 400kc, single 6V6 audio output with 500 Z ohm output

transformer. Serial number is stamped into the chassis between the 6C8

and 6F8 tubes. Serial number is three numerical digits. Highest reported

numerical SN is 948. Two serial numbers have been reported that incorporate the

letter "A" as a prefix, e.g., A059. It's probable that the "A" indicates

"1000" and A059 would be 1059 for a numerical conversion. A578

has also been reported which implies production quantity was over 1500

receivers. As to why the

letter prefix? It may have designated a second production run for the

same contract and was National's way to keep track of the receiver

manufacture (just conjecture.) The ASD may have been a replacement for NC-100ASC (aka

AN/GRR-3) that might have been a "militarized" NC-100XA.

NC-200FG, R-115 (USCG), NC-240C and NC-240CS produced during WWII.

These receivers do not have band spread function. The CS version had

200kc to 400kc band to replace the AM BC band. The R-115 has no crystal

filter, no tone control, no S-meter and no logging scale. Covers 200kc

to 400kc and 500kc to 18mc.

NC-100A, NC-100XA and NC-200 offered in the National section of the

1945 Radio Amateur's Handbook. None of these receivers, or any other

items listed, were actually available during the war and each page of

the catalog states "Priorities are required for all products in this

catalog until otherwise released by the War Production Board." The

intention of the catalog was to show what National was probably going to

have available after the war ended.

In 1945, Schuttig & Co. modified RCL and RCK Airway receivers into

RCP Airway receivers. The RCK-N built during WWII used a 1560kc IF and

tuned 200kc to 800kc and 2.5mc to 23.5mc in five tuning ranges. 6C5

tubes, the detector and the squelch tubes, are replaced with 6J7 tubes

in the RCQ versions.

1946-49

NC-240CS sold to the civilian market in post-war 1945 as a 1946

model. In 1946, National designated the CS version as a "commercial

receiver"

NC-240D returned the band spread function and was sold from

early-1946 up to 1949. Note in SN Log that F-104 is a CS model w/o BS

and that F-478 is a D model with BS. Both receivers are from the same

production run "F" which indicates that this change was rapidly

incorporated. Early NC-240D dials are similar to NC-200 dial with all

four Band Spread scales near the center of the circular arc of the

scales. Later NC-240D dials will have the Band Spread scales alternating

with and located above the General Coverage scales on bands D, C, B and

A.

In 1948, National Electrical Machine Shops (NEMS) modified RCL and

RCK Airway receivers (or parts from these types of receivers) into RCQ

Airway receivers

In 1948, some NC-240CS receivers were produced as RCR Airway

Receivers. The RCR is the last National Airway receiver produced based

on a Moving Coil receiver design. |