RCE SN: 302 - Airport Communication Receiver - Mechanical Rebuild

This restoration was more mechanical and cosmetic than it was electronic. It involved finding and installing correct vintage parts along with correcting other mechanical problems. Additionally, front panel paint "touch-up" and the mechanical approach to "body work" is covered. Further, the methods for operating a vintage receiver on "original parts" is presented.

| I received an e-mail from fellow Vintage Military Radio Net

member WA6OPE asking if I would be interested in a National RCE

Airport Receiver. He included some photos that showed the RCE to

be complete but in rather "rough" condition. A deal was made and

Tom brought the RCE up to the N7RCA Ham Swap Meet in Minden,

Nevada (first weekend in June 2014) for delivery and payment.

Tom had found the receiver in the SF Bay Area, apparently from a

"non-ham" as the RCE had never been worked on or modified since

it had been retired from commercial use. Storage in the SF Bay

Area, with its salt-air environment, is problematic and

long-term storage in a garage or shed can result in significant

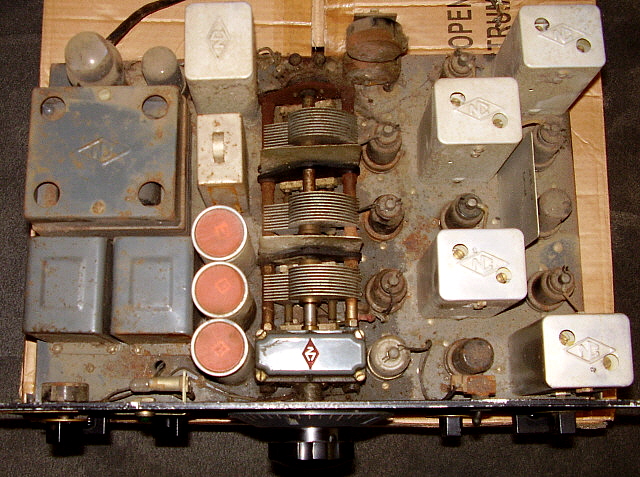

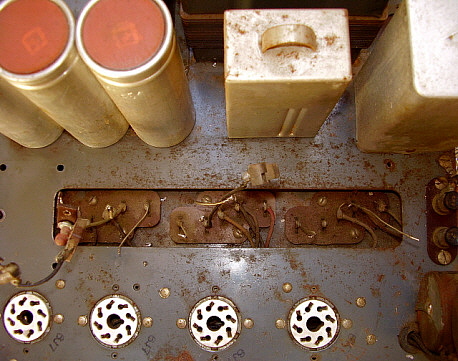

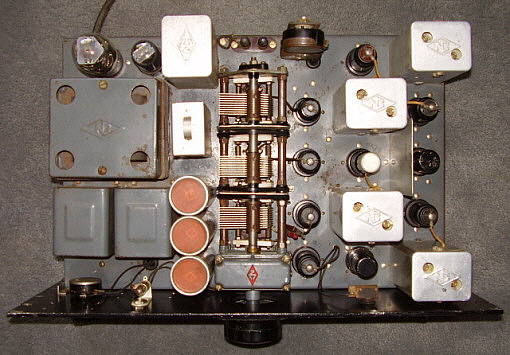

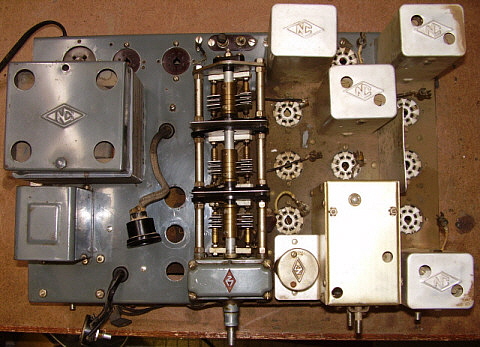

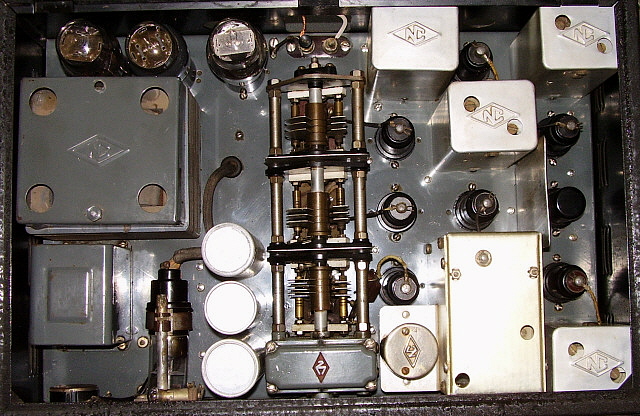

corrosion. The photo of the chassis below shows the typical

surface rust that is found on metal that is stored in unheated

buildings. Not terrible but certainly significant. Fortunately,

the underneath of the chassis was nearly perfect which implies

that condensation was probably responsible for most of the rust.

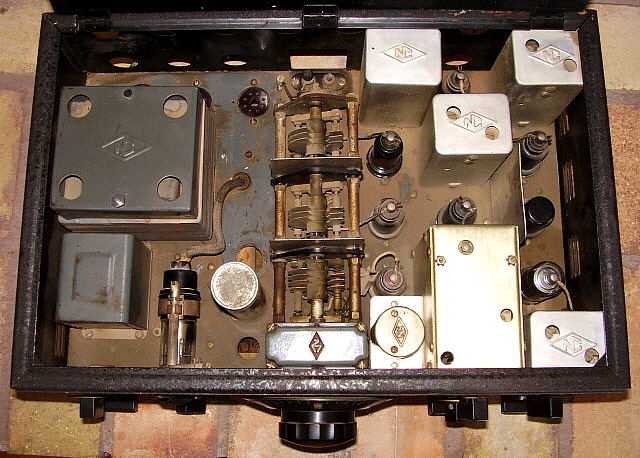

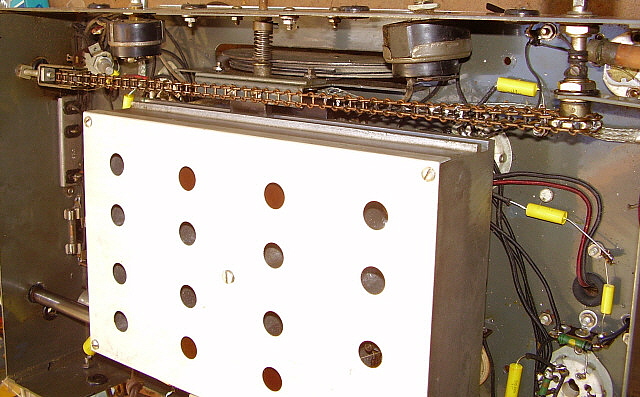

The dust cover being present is somewhat rare. It seems like

many of the Airport receivers now turn up with the dust cover

long-gone. This dust cover is made out of aluminum - the later

Airport receiver dust covers were made out of steel. The

condition of the dust cover is very good but somewhat bent in

the back because the rear screws weren't installed. >>> |

|